- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

PE盘管生产线集高效、精准于一体。它自动化程度高,PLC系统精准调控参数,还能智能诊障;生产效率出众,能持续快速产出。成型精度有保障,管径与性能灵活可变。兼具节能环保优势,且防护周全,安全性强,适配多元生产需求。

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

| Pipe diameter range | Extruder | Main motor | Extrusion output | Production speed |

|---|---|---|---|---|

| 16-63mm | 65/33 | 37kw | 60-140kg | 8—60m/min |

| 63-160mm | 75/33 | 55kw | 100–300kg | 8m/min |

| 75-250mm | 90/33 | 90kw | 160-400kg | 6m/min |

Our company based on years of design and production experience, combined with the actual situation at home and abroad, developed the PE pipe production line fully automated production equipment, including all automation units and peripheral equipment from the extruder, the entire production line is highly automated, easy to operate, continuous production is stable and reliable.

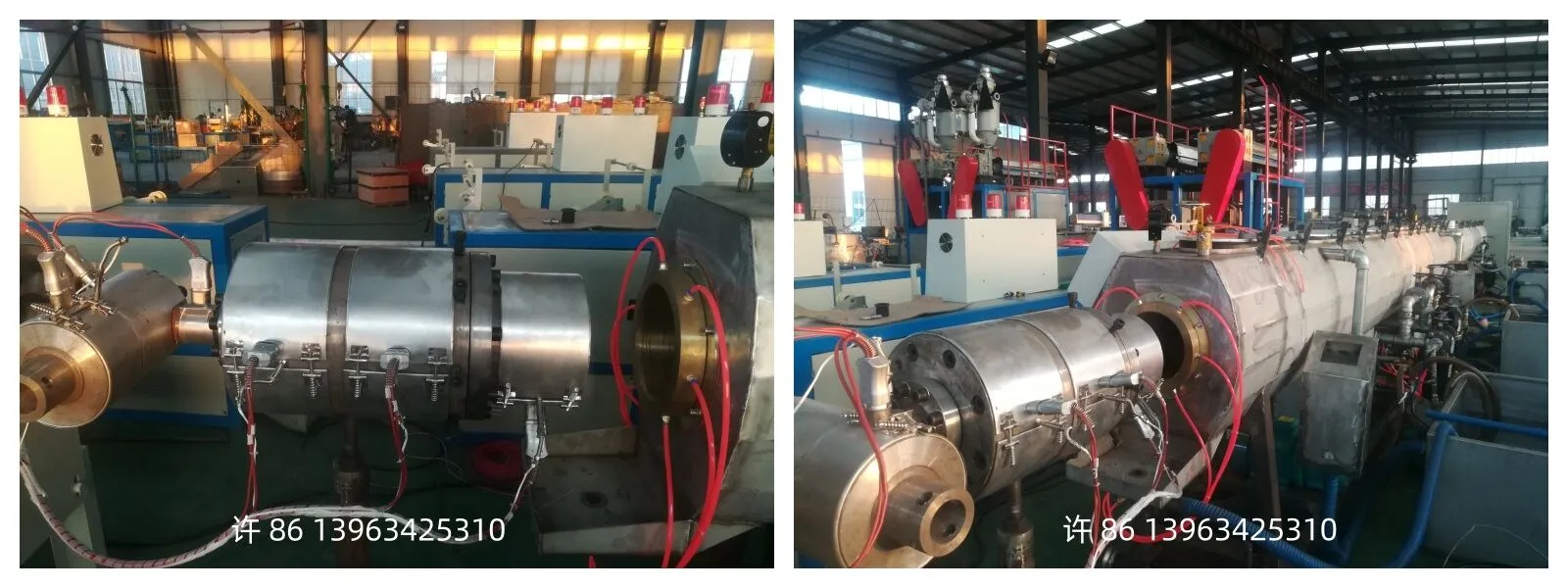

Equipment composition: The production line consists of a control system, an extruder, a machine head, a setting cooling system, a tractor, a cutting device, a winding machine, and a turning rack.

Mold and auxiliary machine: The machine head adopts a newly designed basket type machine head or a spiral shunt type extrusion pipe composite machine head, which has the best design of low melting temperature, small internal stress of the pipe, smooth inner and outer surfaces, convenient adjustment, and uniform discharge. The diameter sleeve adopts a unique slotting process and water ring cooling to ensure the forming accuracy of the pipe.

Mold and auxiliary machine: The machine head adopts a newly designed basket type machine head or a spiral shunt type extrusion pipe composite machine head, which has the best design of low melting temperature, small internal stress of the pipe, smooth inner and outer surfaces, convenient adjustment, and uniform discharge. The diameter sleeve adopts a unique slotting process and water ring cooling to ensure the forming accuracy of the pipe.

The vacuum sizing cooling tank is made of stainless steel, high-power water pump and special spray design for efficient cooling.

The traction device adopts frequency conversion speed regulation system to ensure synchronous traction.

The extruder adopts a high-reliability hard-tooth surface gearbox, which brings stable operation and long service life.

The whole machine adopts advanced PLC and color LCD screen control system, with perfect alarm system, good Chinese man-machine interface, operation is very convenient.

Application:

Application:The PE pipe production line has a very wide range of applications. In the field of municipal engineering, the pipes it produces are widely used for laying urban water supply and drainage pipes. With its anti-corrosion and pressure resistance characteristics, it ensures the smooth circulation of urban water. In agriculture, it is the “main force” of drip irrigation and sprinkler irrigation systems, accurately conveying water sources, saving water and increasing efficiency, and helping crops thrive. For construction projects, lightweight and easy-to-install PE pipes play a role in indoor water supply and drainage and floor heating systems, reducing the difficulty of construction. In industry, it can safely transport some chemical raw materials, meet special material transmission needs, and adapt to multiple scenarios.

Video display:

Video display:

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine