- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

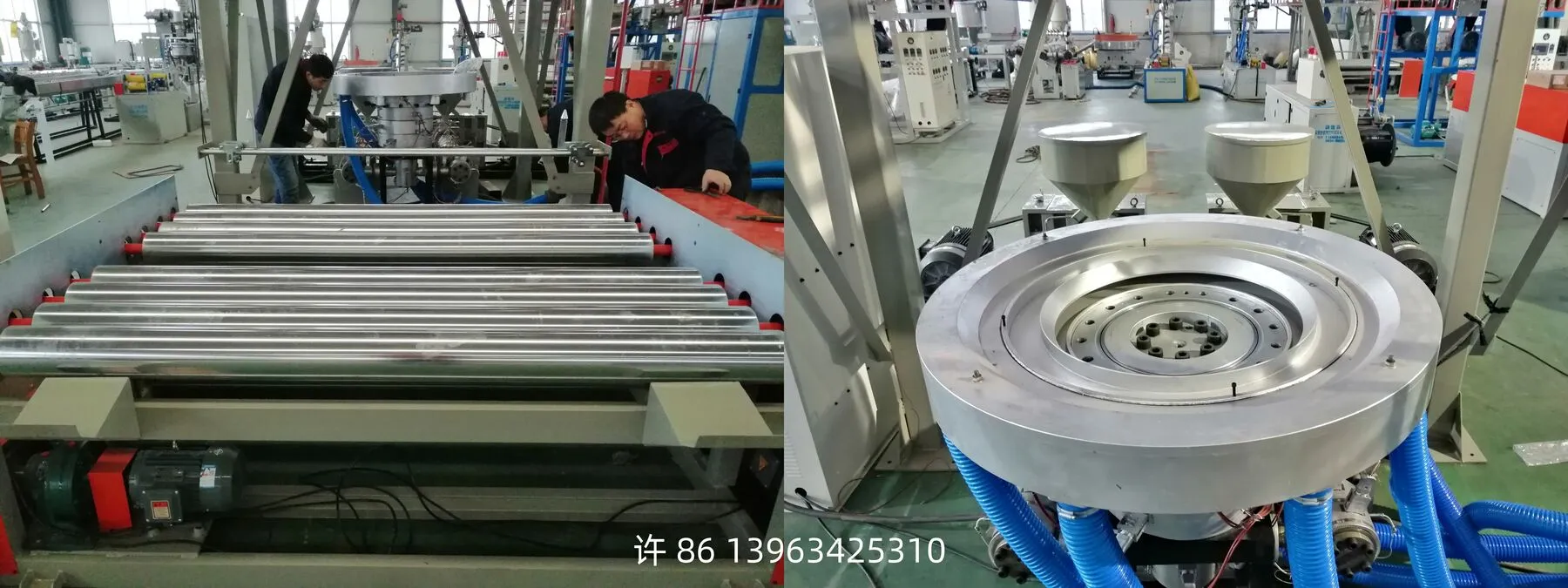

The two-color mulch film unit is specially designed for mulch film production. Equipped with multiple high-quality extruders, it can process two-color raw materials synchronously and accurately shape two-color mulch film. It has the advantages of wide width and thickness flexible regulation. With air-cooled and water-cooled high-efficiency cooling and automatic winding system, it is efficient and energy-saving. The two-color mulch film produced helps agricultural fine management, efficiency and income increase.

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

| Items | Details |

|---|---|

| Product Name | Two-color mulch film unit |

| Extruder Configuration | Usually equipped with two or more extruders of different specifications. The common screw diameters range from 65mm to 90mm, with a length-to-diameter ratio of 28 – 33, to meet the simultaneous extrusion requirements of raw materials of different colors and achieve the two-color effect. |

| Maximum Extrusion Capacity | The overall maximum extrusion capacity of the unit is approximately 150 – 350 kg/h. The specific value varies according to the equipment model and configuration differences. |

| Screw Material | Made of high-quality alloy steel, it has high strength, wear resistance, and corrosion resistance, ensuring long-term stable operation and reducing maintenance frequency. |

| Die Head Design | A specially designed co-extrusion die head precisely controls the distribution and fusion of the two-color materials, enabling the production of two-color mulch films with clear boundaries and regular patterns. The diameter of the die head is adjusted from 600 to 1500 mm according to the width of the mulch film to be produced. |

| Mulch Film Width Range | Capable of producing two-color mulch films with widths ranging from 800 mm to 4000 mm, suitable for various farmland usage scenarios of different scales. |

| Mulch Film Thickness Range | The thickness range is usually from 0.008 to 0.02 mm. Different thicknesses are used for different planting needs. Thinner mulch films have lower costs, while thicker ones are more durable. |

| Cooling System | Equipped with a combined air-cooling and water-cooling cooling method. First, air cooling rapidly reduces the temperature initially, and then water cooling further consolidates the shaping, improving the forming quality and production efficiency of the mulch film. |

| Traction Device | A high-precision variable-frequency speed-regulating tractor is adopted, with a traction speed range of 3 – 30 m/min, which can smoothly pull the mulch film forward and adapt to different production rhythms. |

| Winding Device | Mostly a two-station automatic winder, with a winding diameter of up to 1500 mm, facilitating quick roll change, ensuring continuous production, and reducing downtime. |

| Applicable Raw Materials | Mainly polyethylene (PE)-based raw materials, such as low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE). Some can also be added with functional masterbatches. |

| Degree of Automation | It has a relatively high level of automation. Most processes, from raw material transportation, extrusion, cooling to traction and winding, are automated, reducing labor costs and operational errors. |

| Overall Dimensions | Due to different equipment specifications, it is approximately 12 – 25 meters in length, 3 – 5 meters in width, and 2 – 4 meters in height. |

| Total Installed Power | Approximately 100 – 300 kW. Different power configurations correspond to units with different production capacities. |

Product features:

Product features:The two colors can be cleverly integrated to form a two-color mulch with clear boundaries. This is not only beautiful, but also can be used to distinguish planting areas and crop varieties, which is convenient for agricultural management.

Special co-extrusion die, precise control of two-color material distribution, ensure uniform film thickness, accurate thickness falling in 0.008-0.02mm, flexible width adaptation 800-4000mm, fit a variety of fields.

The cooling system combining air cooling and water cooling first cools down quickly and then firmly forms, which not only improves production efficiency, but also reduces energy consumption and accelerates product output.

perfectly compatible with LDPE, LLDPE and other polyethylene raw materials, and can also add functional masterbatches on demand to give the mulch anti-aging, weeding and other characteristics.

The whole process of automatic control of raw material transportation to all aspects of coiling, reducing manpower investment and operation errors, stable product quality, low defective rate.

1. Vegetable planting,in all kinds of vegetable greenhouses and open-air vegetable fields, two-color mulch film comes into play. For example, when planting beans and cucumbers in spring, black and silver mulch, the silver side up can reflect sunlight, replenish light, heat and moisturize warm vegetables; black side down can inhibit the growth of weeds, avoid weeds and vegetables competing for nutrients, reduce the cost of artificial weeding, and help vegetables thrive.

2. Fruit cultivation, there are many benefits of laying two-color mulch film in orchards. For strawberry planting, red and black two-color mulch film can not only attract insects to assist in pollination, but also maintain soil moisture and adjust ground temperature, create a suitable environment for strawberry roots, improve fruit quality and yield, and make strawberries brighter in color and sweeter in taste.

3. Flower cultivation, flower production has strict environmental requirements, and the two-color mulch film can be adjusted on demand. The combination of white and blue mulch film, white helps light scattering, so that the flowers receive light more evenly, blue can prevent insects to a certain extent, protect delicate flowers from wind and rain, control temperature and humidity, and ensure the beautiful shape of flowers and the punctual flowering period.

4. Economic crop planting, such as tobacco and cotton, two-color mulch film can meet special growth needs. With brown and silver mulch film, brown accelerates soil warming, promotes early germination of seeds and early development of seedlings; silver sunscreen is drought-resistant, protects crops from high temperature burns in the later stage of growth, and stabilizes the harvest.

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine