- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

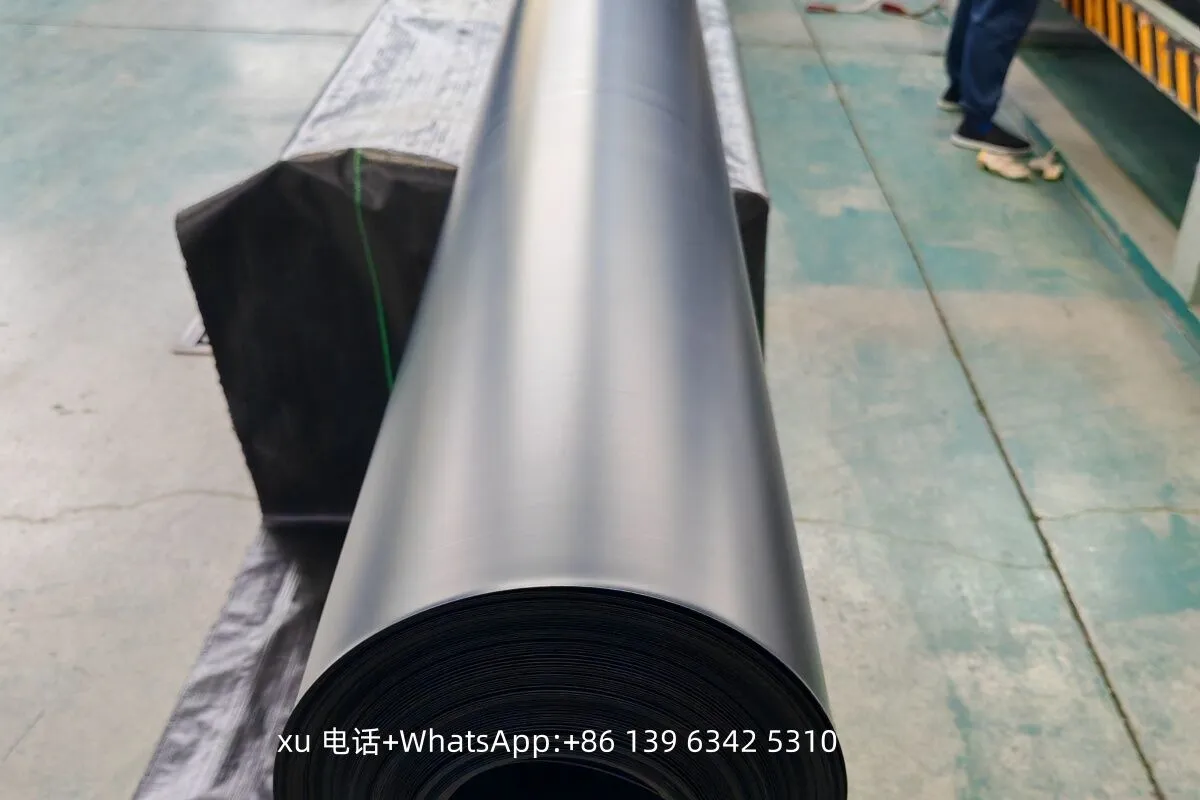

The 8-meter three-layer co-extrusion geomembrane unit has an ultra-wide capacity of 8 meters. It adopts a three-layer co-extrusion process to simultaneously extrude and compound raw materials with different characteristics for precise molding. It has a high degree of automation, stable operation and outstanding production efficiency. It can produce high-quality and multi-functional geomembrane, which is widely used in large-scale anti-seepage projects such as water conservancy and environmental protection.

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

| Aspect | Details |

|---|---|

| Definition | A three-layer co-extrusion geomembrane with a width of 8 meters. It’s made by simultaneously extruding three polymer layers, which are often polyethylene-based, to combine different material properties. |

| Material Composition | Commonly consists of high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), etc. The different layers can be customized to offer specific functions, like an outer layer for UV resistance, a middle layer for strength, and an inner layer for anti-seepage. |

| Physical Properties | Thickness: Ranges from 0.75mm – 3mm typically, meeting various project requirements. Tensile Strength: High tensile strength, able to withstand stretching forces, with values often exceeding 20MPa in longitudinal and transverse directions, ensuring it doesn’t rupture easily under load. Elongation at Break: Can have an elongation percentage of around 700% at break, providing good ductility. |

| Production Process | Through co-extrusion technology, three polymer melts are pushed through a single die simultaneously. This precision process allows for seamless integration of layers, creating a homogeneous yet multi-functional membrane. |

| Advantages | Large Coverage: The 8-meter width reduces the number of seams during installation, minimizing potential leakage points. Anti-seepage: Offers excellent anti-seepage performance, with a very low permeability coefficient, protecting soil and water resources from pollution. Durability: Resistant to chemicals, UV radiation, and abrasion, suitable for long-term outdoor use. |

| Applications | Landfills: Lines the landfill base and slopes to prevent leachate seepage. Water Reservoirs: Forms anti-seepage barriers in artificial lakes, dams, and water storage ponds. Mining: Covers tailings ponds to contain mining waste liquids. |

1. Wide width and high yield: width up to 8 meters, single output area is large, significantly reduce the number of geomembrane splicing in large-scale projects, improve laying efficiency. Three-layer co-extrusion technology allows multi-raw materials to be formed simultaneously, with a compact production process and large daily output, which efficiently meets the needs of large-scale projects.

2. Excellent quality: Each layer has a clear division of labor. Through co-extrusion close fitting, the middle layer strengthens physical properties and improves puncture resistance and tensile strength. The outer layer guarantees weather resistance and corrosion resistance. The overall thickness is uniform, without weak points, and the anti-seepage and durability are excellent.

3. Strong material adaptation: Thanks to the three-layer structure, it has high acceptance of HDPE, LLDPE and other plastic raw materials and various functional additives. It can be flexibly allocated on demand to customize geomembrane suitable for different geological and environmental conditions.

4. Intelligent control: Equipped with advanced automatic control system, precise control of temperature, pressure, extrusion speed and other parameters, reduce manual intervention errors, not only make the production process stable, but also real-time monitoring of faults, rapid early warning and maintenance. 5. Cost-effective: High production efficiency dilutes fixed costs, and high-quality products reduce follow-up maintenance investment. And precise material use avoids waste, saving costs for enterprises and projects from production to service cycle.

8-meter three-layer co-extrusion geomembrane units have diverse applications. In landfill projects, they act as reliable liners, preventing the seepage of harmful leachate into the soil and groundwater, safeguarding the environment. For reservoir construction, these geomembranes form effective anti-seepage barriers, reducing water loss. In mining areas, they are laid on tailings ponds, curbing the spread of contaminants. Their large width of 8 meters minimizes seams, enhancing overall anti-seepage performance and making them a go-to choice for major infrastructure projects demanding strict seepage control.

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine