- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

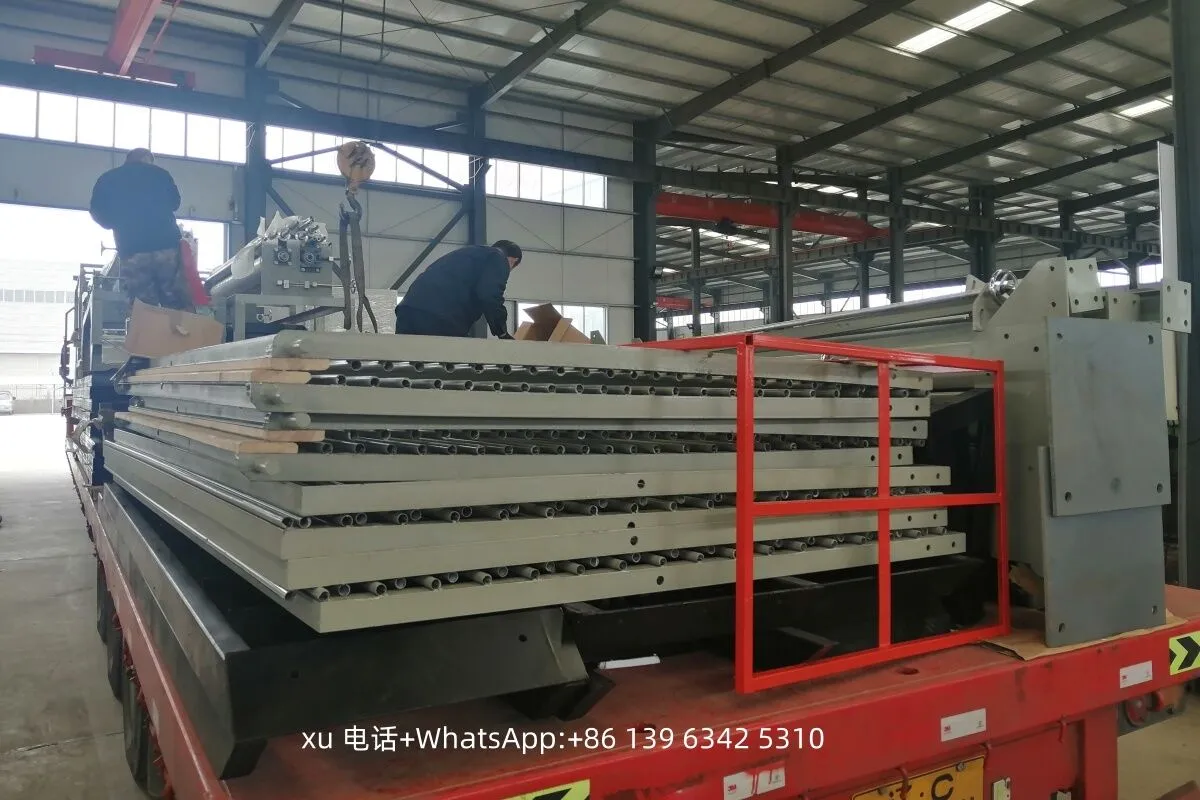

Agricultural plastic film equipment is the right assistant of agricultural production. It integrates advanced technology, is full of power, and all components work together. Accurately adapt to a variety of raw materials, flexibly adjust parameters, and efficiently produce durable and functional agricultural plastic film. It is easy to operate and maintain, and timely delivers high-quality plastic film for spring plowing and autumn planting.

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

| Aspect | Details |

|---|---|

| Definition | Agricultural film equipment refers to a set of machinery used for the production of various agricultural films. These films, typically made from polyethylene or polyvinyl chloride, are essential for modern farming, serving functions like soil warming, moisture retention, and pest prevention. |

| Main Types | – Blown Film Extrusion Machines: – Single-layer: Ideal for producing basic, single-layer agricultural films. They have a simple structure, with a single extruder melting the polymer resin and blowing it into a tubular film. This type is cost-effective for common greenhouse or mulch film needs. – Multi-layer: Consist of multiple extruders working in tandem. They can create films with different layers, each layer having unique properties such as enhanced strength, UV resistance, or improved gas permeability. These are used for high-end agricultural applications. – Casting Film Equipment: This machinery spreads the molten polymer onto a chilled roll, creating flat films. It’s suitable for making thinner, more uniform films with high transparency, often used for packaging fresh produce. |

| Key Components | – Extruder: The heart of the equipment, responsible for melting and homogenizing the polymer granules. It consists of a barrel, screw, and heating elements. The screw rotates to convey the resin forward while applying pressure and heat to transform it into a molten state. – Die Head: Shapes the molten polymer into either a tubular (for blown film) or flat (for casting film) form. Die heads can be adjusted to control the film’s width and thickness. – Cooling System: For blown film, an air ring cools the inflated tubular film from the outside. In casting film, a series of chilled rolls rapidly cools the flat molten film. Proper cooling is vital for setting the film’s physical properties. – Winding System: Rolls up the finished film neatly onto spools for easy storage and transportation. It often has tension control to ensure the film is wound evenly. |

| Production Process | 1. Resin Loading: Polymer granules are loaded into the extruder’s hopper. 2. Melting and Mixing: Inside the extruder, the resin is heated and mixed with additives (if any) to form a homogeneous melt. 3. Shaping: The molten polymer passes through the die head to take on the appropriate film shape. 4. Cooling: The newly formed film is cooled to solidify its structure. 5. Winding: The cooled film is wound onto a spool, completing the production cycle. |

| Quality Control Parameters | – Thickness Tolerance: Agricultural films must meet strict thickness requirements. Deviations can affect functions like heat retention and durability. For example, greenhouse films typically have a tolerance of ±0.02 – 0.05 mm. – Tensile Strength: Determines how well the film can withstand stretching forces during installation and use. Higher tensile strength ensures the film won’t easily tear. – Elongation at Break: Reflects the film’s flexibility. Adequate elongation allows the film to stretch without rupturing under stress. – Transparency: For greenhouse films, high transparency is crucial as it affects light transmission and crop growth. Measured as a percentage, clear films should have transparency values above 80 – 90%. |

| Applications | – Greenhouse Cultivation: Transparent greenhouse films trap sunlight, creating a warm environment for growing vegetables, fruits, and flowers out of season. – Mulch Film Use: Black or colored mulch films cover the soil, suppressing weeds, retaining moisture, and warming the ground for better crop germination and growth. – Fruit and Vegetable Packaging: Thin, clear casting films are used to package fresh produce, protecting it from damage, moisture, and light while allowing visibility for consumers. |

| Advantages | – Customization: Can produce films with different thicknesses, colors, and properties to suit diverse agricultural needs. – High Efficiency: Modern equipment can quickly produce large quantities of films, meeting the demands of large-scale farming. – Cost-Effective: By enabling on-site production or bulk manufacturing, it reduces the overall cost of agricultural films for farmers. |

high-quality screws and die heads are used, and the plasticization is uniform. The blown agricultural plastic film has excellent puncture resistance and tensile resistance. It can withstand field labor, wind, sun and sand and gravel friction. It has a long service cycle and reduces frequent replacement costs. Good functionality: anti-aging, dripping, weeding and other additives can be added on demand to achieve multi-functional integration, which can not only prolong the life of the plastic film, but also help retain moisture, control grass, and serve the growth of crops.

The equipment has strong power, and all links are closely connected. It can stably produce a large number of agricultural plastic films in a short period of time to meet the urgent needs of the peak period of concentrated film such as spring plowing and autumn planting. Flexible regulation: By precisely adjusting parameters such as blowing ratio, traction speed, temperature, etc., mulch films of different thicknesses and widths can be manufactured, which is suitable for a variety of planting scenarios and crop spacing.

It can handle common raw materials such as polyethylene and polyvinyl chloride, and is also compatible with composite raw materials mixed with special additives. It fully exploits the characteristics of raw materials and enriches the functions of mulch films.

Equipped with an intuitive operation interface, workers can get started quickly, easily set parameters, monitor the production process, and reduce the difficulty of training and labor costs. Easy maintenance: The layout of key components is reasonable, the maintenance channel is sufficient, the commonly used parts are standardized, and the maintenance and replacement are rapid, which shortens the downtime.

Application:

Application:Agricultural film equipment plays a pivotal role in modern farming. In vegetable cultivation, it churns out transparent films that cover the fields, creating mini greenhouses. These films trap heat, accelerating the growth of tomatoes, cucumbers, and more, and also shield crops from pests and harsh weather. For fruit orchards, the equipment manufactures anti-frost films. When spring brings erratic temperatures, these films safeguard tender fruit buds, ensuring a bountiful harvest. In flower farming, colored agricultural films can be produced, regulating light penetration to boost flower coloring and growth, enhancing both quality and marketability.

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine