- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

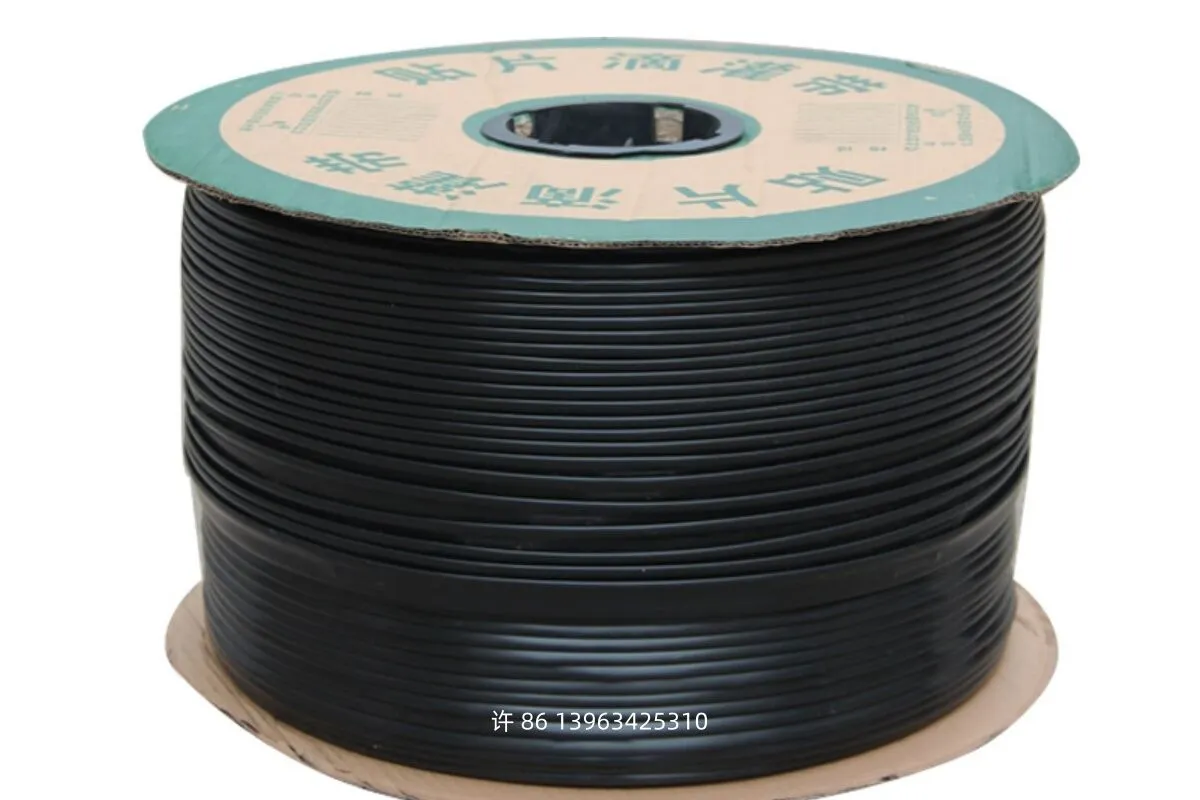

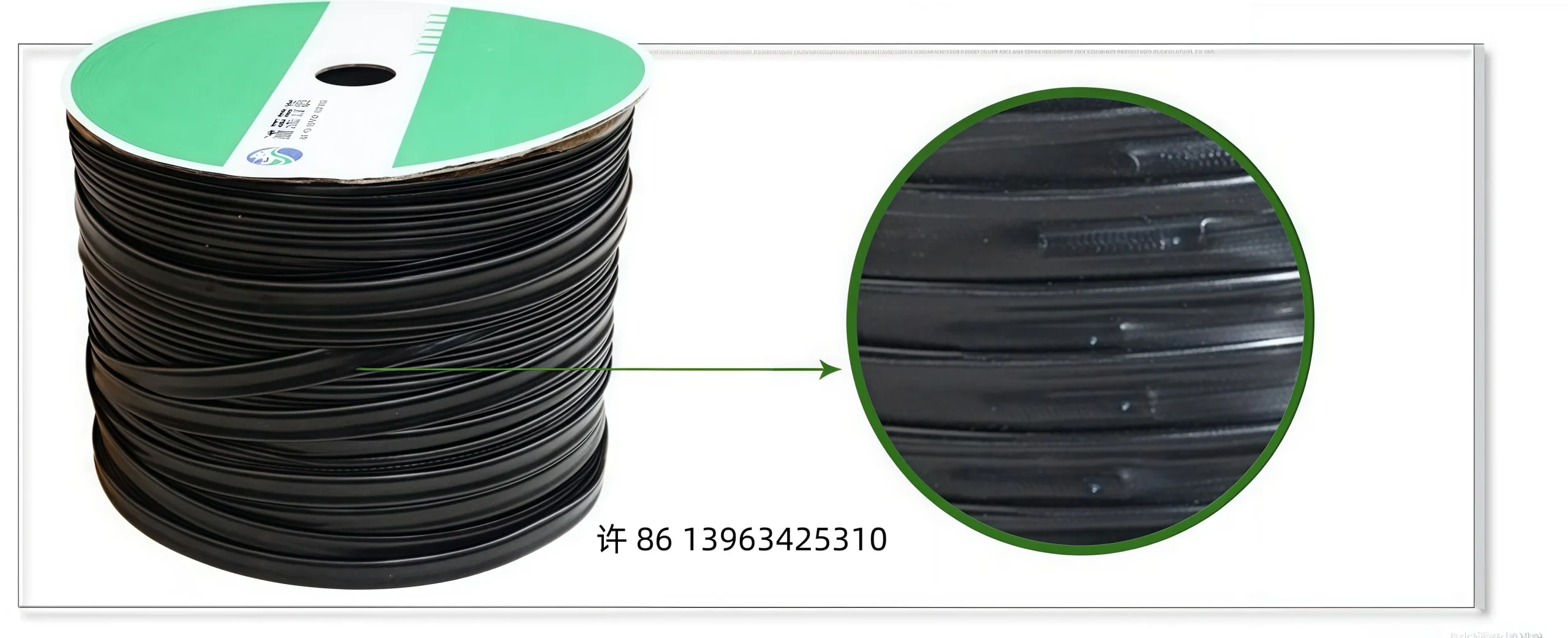

Inlaid patch type drip irrigation tape is an efficient water-saving irrigation tool. It inlays the flat dripper inside the inner wall of the pipe tape. The integrated design makes installation convenient. The labyrinth flow channel ensures stable water flow. The spacing between drippers is flexible and can be customized as needed. It also has a built-in filter window to prevent clogging. Commonly made of LLDPE material, it is anti-aging and lightweight. It is widely used in the planting of fruits, vegetables and field crops, saving water and increasing efficiency.

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

| Project | Details |

|---|---|

| Structural features | Inlaid flat emitter, closely integrated with the pipe belt. |

| Pipe diameter | Common specifications are 12mm, 16mm, 20mm, 22mm. |

| Wall thickness | The range is between 0.15 and 0.6mm, and the common wall thicknesses are 0.2mm, 0.3mm, and 0.4mm. |

| Working pressure | 0.02 – 0.25MPa, ideal working pressure is about 0.1MPa |

| Traffic | The common flow rate is 2-3L/h, and the flow rate of some drippers is divided into 1.1L/h, 1.38L/h, 2.0L/h, 3.0L/h, and 4L/h. Various options are available |

| Dripper spacing | Customized on demand, common spacing 100mm, 150mm, 200mm, 300mm, flexible range 10cm – 1m |

| Maximum laying distance | Usually no more than 80 meters. In practice, a laying distance of about 50 meters has a better effect. Some have slightly stronger capabilities for long-distance laying. |

| Anti-clogging performance | With a built-in filter window and a maze-like flow channel design, it has self-flushing ability and good anti-clogging effect. |

| Material | Mainly use LLDPE (linear low density polyethylene) and add anti-aging and anti-ultraviolet components. |

| Applicable scenario | Widely used in greenhouse vegetables, fruit trees, flowers, tea gardens, economic forest trees and field cash crops drip irrigation |

Product features:

Product features:Integration of dripper and pipe belt: The dripper is embedded on the inner wall of the pipe belt to form a whole. No additional dripper is required during installation. The operation is simple and quick, which reduces the installation cost and time. The overall structure is more solid and it is not easy to have problems such as dripper falling off.

Flexible dripper spacing: Different dripper spacings can be customized according to the planting spacing and irrigation needs of different crops, such as the common 100mm, 150mm, 200mm, 300mm, etc., which can better meet the irrigation requirements of various crops and accurately deliver water to the roots of each crop.

Labyrinth flow channel: The labyrinth flow channel design is adopted to make the water flow form turbulence in the flow channel, which has a certain pressure compensation effect, which can ensure that the water output of the dripper is relatively stable under different working pressures, and the irrigation uniformity is high, which is conducive to the uniform growth of crops.

Self-filtering window: Each dripper is equipped with a self-filtering window, which can initially filter impurities in the water at the water inlet, block larger particles of silt, debris, etc. from entering the flow channel, reduce the risk of dripper blockage, and also reduce the dependence on water source filtration equipment.

Good anti-blocking performance: In addition to the self-filtering window, its wide and long flow channel design further enhances the anti-blocking ability. The characteristics of full-stable flow and self-flushing enable the water flow to automatically flush impurities in the flow channel during irrigation and keep the flow channel unobstructed.

Good pressure compensation: Some embedded patch-type drip irrigation belts are equipped with high-elasticity high-quality pressure compensation sheets. Within the pressure change range of 0.5-4bar, the dripper flow rate remains basically unchanged, which can adapt to different terrains and irrigation conditions, especially for narrow and long plots, mountainous areas and areas with large terrain undulations.

Excellent material: Usually high-quality materials such as LLDPE (linear low-density polyethylene) are used, and anti-aging agents and ultraviolet absorbers are added. It has the characteristics of anti-corrosion, anti-aging, high strength, wear resistance, etc. It can be used outdoors for a long time, extending the service life of the drip irrigation belt.

Long laying length: small head loss along the way, single pipe laying length can reach more than 80 meters, the number of branches and valves is relatively small, reducing the workload and cost of pipeline laying, and also facilitating management and maintenance.

Light weight: light overall weight, easy to carry, arrange and collect in the field, can reduce labor intensity, improve work efficiency, and also facilitate mechanized laying, suitable for large-scale agricultural irrigation.

Low cost: Compared with other irrigation methods, the initial investment of the embedded patch drip irrigation belt is small, the unit production cost is low, the product unit price is low, and due to its water-saving, fertilizer-saving, and labor-saving characteristics, long-term use can reduce agricultural production costs.

Water-saving, fertilizer-saving and efficiency-enhancing: Through precise irrigation, water and fertilizer are directly delivered to the roots of crops, reducing water evaporation and fertilizer loss, improving the utilization rate of water and fertilizer, saving a lot of water resources and fertilizer, and helping to maintain soil structure, improve crop quality, and achieve increased production and efficiency.

Application:

Application:The embedded patch drip irrigation belt is widely used. In greenhouses, it accurately supplies water to delicate vegetables and flowers, and discharges water through the drippers to prevent water from splashing on the leaves and causing diseases. It can also apply fertilizers on demand to help the plants grow healthily. In orchards, according to the distribution characteristics of the fruit tree roots, drip irrigation belts are laid reasonably to ensure that each fruit tree has sufficient water and improve fruit yield and quality. In large areas of field cash crops, such as cotton and corn fields, it overcomes the problem of complex terrain and lays stable water supply over long distances, which saves water and labor, greatly improving agricultural production efficiency.

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine