- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

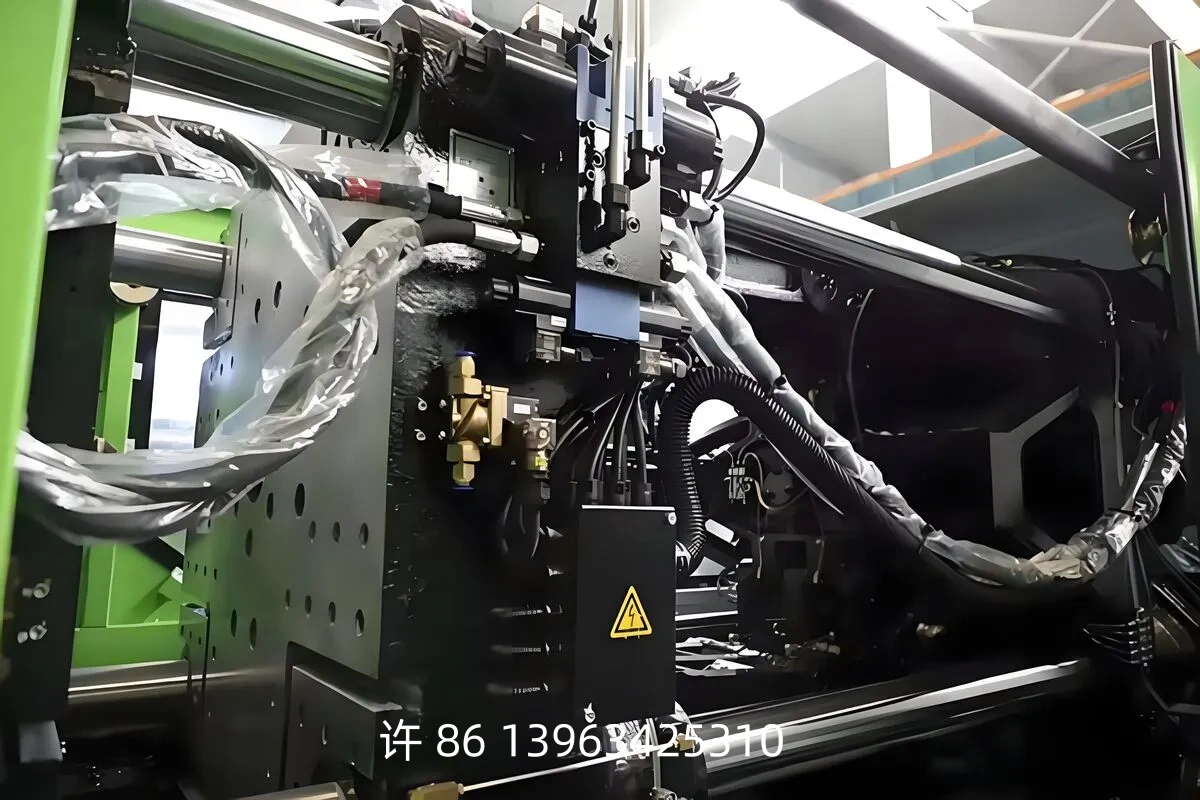

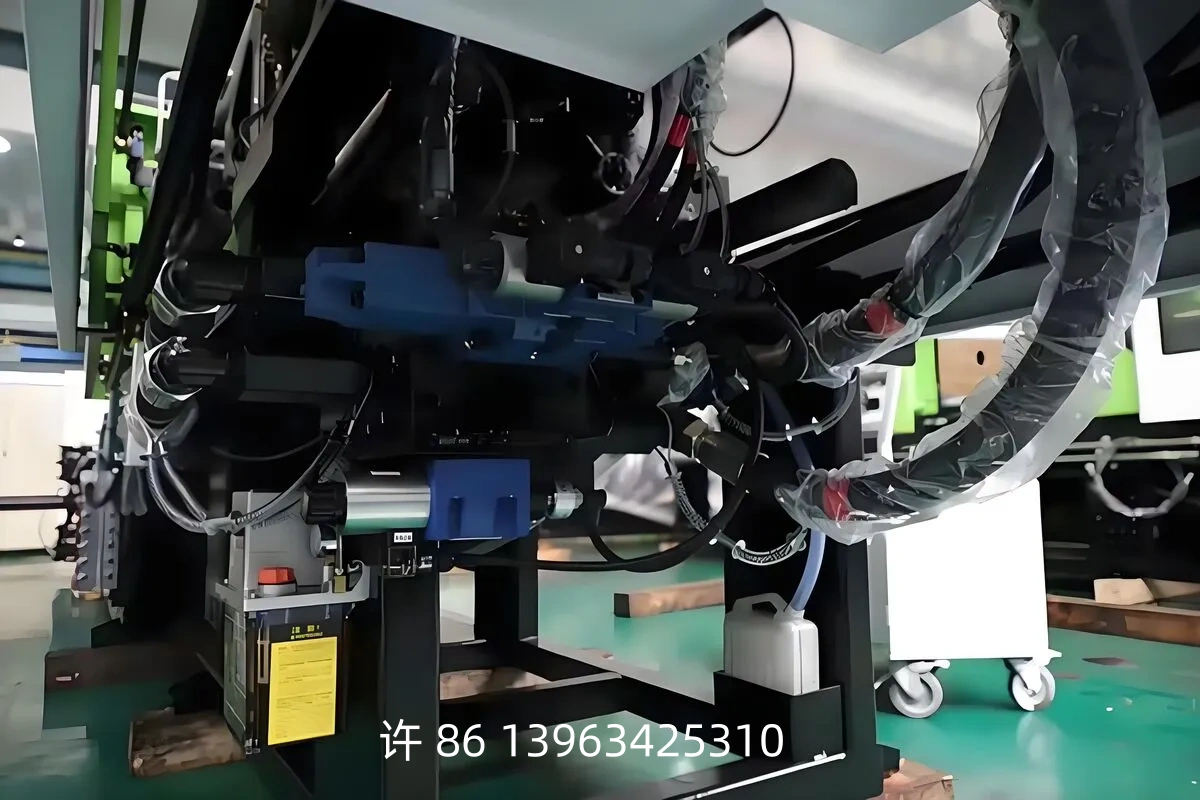

Large-scale two-plate injection molding machine, fully hydraulic type two-plate clamping structure, the force of the mold is balanced, the clamping force is precisely controlled, and there is no tail tie rod support mechanism, which is convenient and adaptable to larger mold installation. Two-plate clamping structure, reducing the consumption of steel and other raw materials, reducing the floor area of the equipment, closed-loop control of the injection pressure, increasing the speed of injection, and improving the accuracy of the product. Standard modular control system, to achieve a simple and reliable wiring on site, reliable control performance, convenient and concise maintenance. Large-size man-machine exchange interface, intelligent control mode. The design of the clamping part and the injection unit building block, which greatly meets the various needs of different customers. Parallel multi-pump servo control system, maximizing energy savings.

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

Product details:

Product details:| Model number | CS600/IU4250 | CS700/IU5600 | CS880/IU7300 | CS1050/IU9300 | CS1250/IU11000 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Injection part | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C |

| Injection volume cm ^ 3 | 2030 | 2610 | 3261 | 2614 | 3308 | 4084 | 3563 | 4398 | 5322 | 4712 | 5702 | 6786 | 5702 | 6786 | 7963 |

| Injection volume (PS) g | 1830 | 2401 | 3000 | 2405 | 3043 | 3757 | 3278 | 4046 | 4896 | 4335 | 5246 | 6243 | 5246 | 6243 | 7327 |

| Screw diameter mm | 75 | 85 | 95 | 80 | 90 | 100 | 90 | 100 | 110 | 100 | 110 | 120 | 110 | 120 | 130 |

| Screw aspect ratio Sc | 24 | 21 | 19 | 24 | 21 | 19 | 23 | 21 | 19 | 23 | 21 | 19 | 23 | 21 | 19 |

| Injection rate to air, cm^3/s. | 442 | 575 | 718 | 491 | 621 | 766 | 621 | 767 | 928 | 773 | 935 | 1113 | 926 | 1102 | 1295 |

| Injection pressure Mpa | 210 | 163 | 131 | 213 | 169 | 137 | 206 | 167 | 138 | 196 | 162 | ·136 | 193 | 162 | 138 |

| Maximum plasticizing capacity (PS) g/s | 82 | 119 | 166 | 93 | 133 | 182 | 123 | 169 | 225 | 160 | 210 | 273 | 210 | 273 | 355 |

| Maximum screw speed rpm | 160 | 160 | 145 | 130 | 130 | ||||||||||

| Injection speed mm/s | 100 | 100 | 100 | 100 | 98 | ||||||||||

| Injection stroke mm | 460 | 520 | 560 | 600 | 600 | ||||||||||

| laminated part | |||||||||||||||

| Junction force Kn | 6000 | 7000 | 8800 | 10500 | 12500 | ||||||||||

| Die transfer stroke mm | 950-1550 | 1000-1750 | 1100-1850 | 1300-2000 | 1450-2250 | ||||||||||

| Tie rod inner spacing mm | 960*860 | 1060*960 | 1160*1020 | 1260*1120 | 1360*1220 | ||||||||||

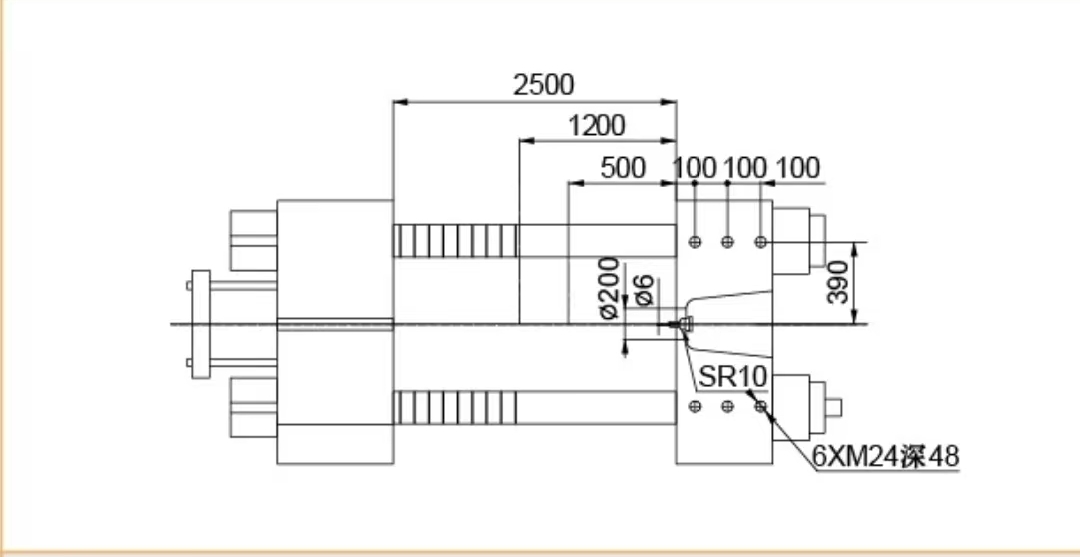

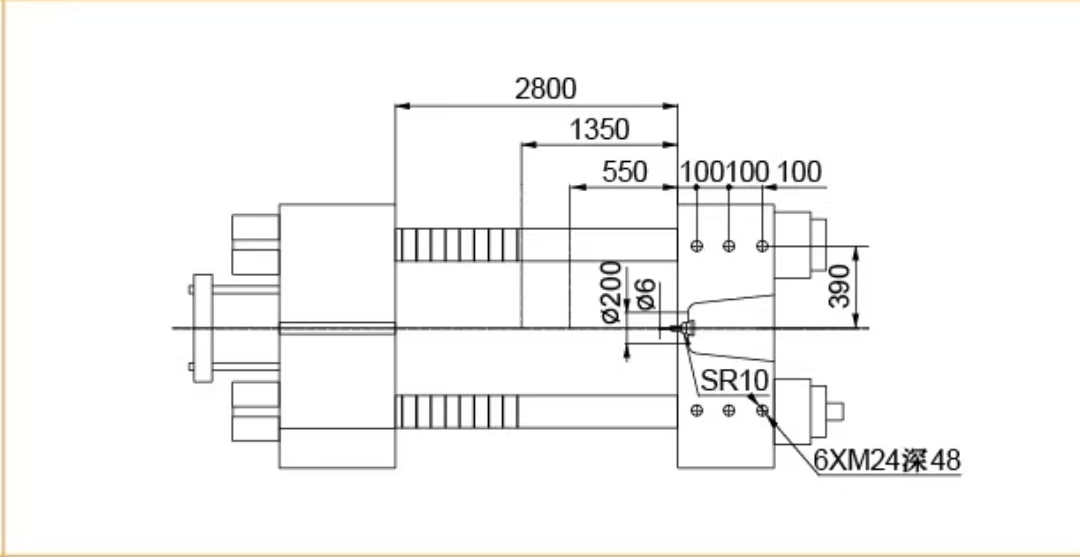

| Maximum template distance mm | 1900 | 2150 | 2300 | 2500 | 2800 | ||||||||||

| Maximum die thickness mm | 950 | 1150 | 1200 | 1200 | 1350 | ||||||||||

| Minimum film thickness mm | 350 | 400 | 450 | 500 | 550 | ||||||||||

| Ejection stroke mm | 300 | 300 | 300 | 350 | 350 | ||||||||||

| Maximum ejection thrust Kn | 232 | 232 | 232 | 330 | 330 | ||||||||||

| Electronic control part | |||||||||||||||

| System pressure Mpa | 17.5,21 | 17.5,21 | 17.5,21 | 17.5,21 | 17.5,21 | ||||||||||

| Oil pump motor power Kw | 75+7.5 | 55+31+7.5 | 65+31+7.5 | 65+55+7.5 | 65*2+7.5 | ||||||||||

| Storage motor power (optional) ※ Kw | 53 (integrated direct drive) | 55 (motor + gearbox) | 55 (motor + gear) | 55 (motor + gear) | 55 (motor + gear) | ||||||||||

| Electric heating power Kw | 40 | 45 | 55 | 60 | 65 | ||||||||||

| temperature control zone | 5 | 6 | 6 | 6 | 6 | ||||||||||

| Other | |||||||||||||||

| Fuel tank capacity L | 750 | 900 | 1000 | 1200 | 1400 | ||||||||||

| Total weight t | 23 | 28 | 35 | 43 | 53 | ||||||||||

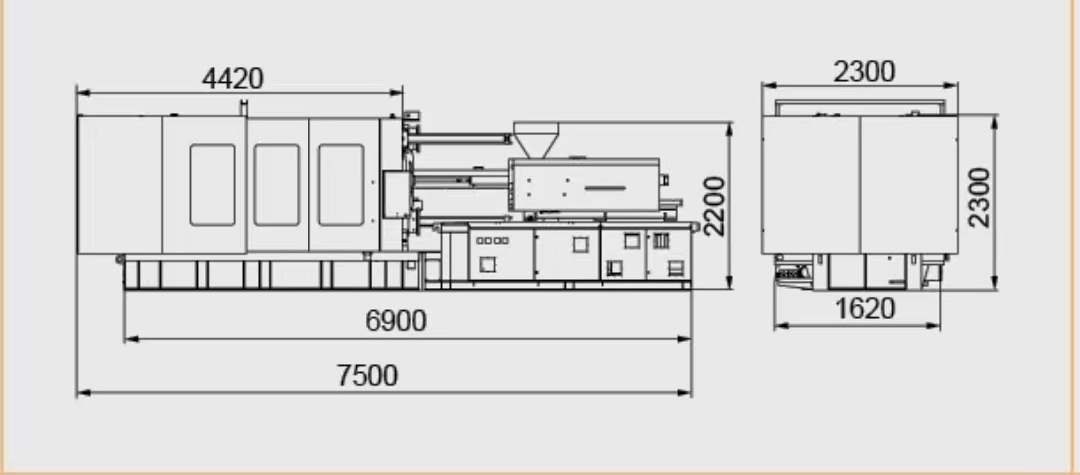

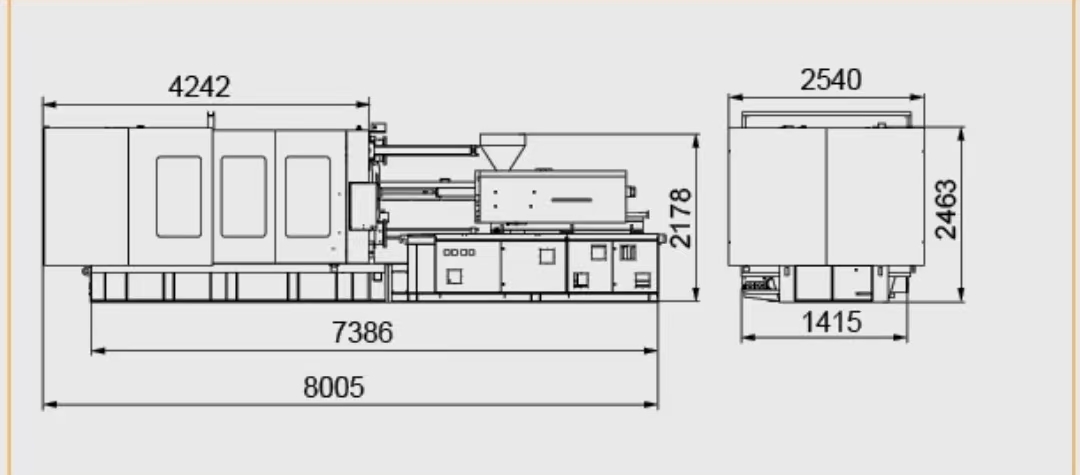

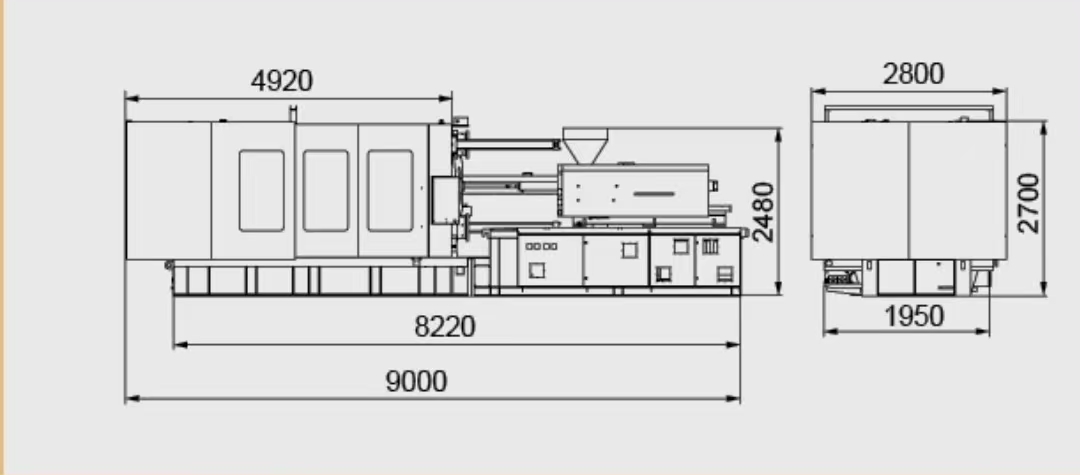

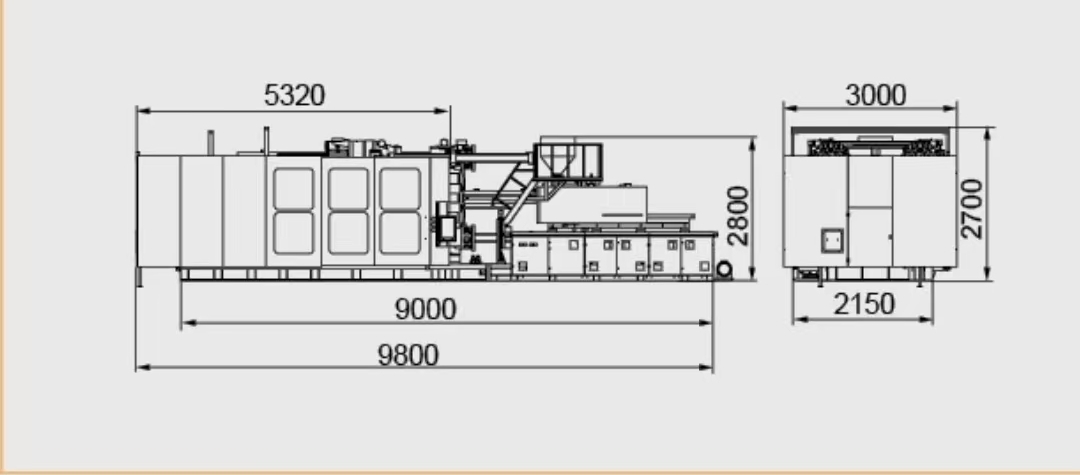

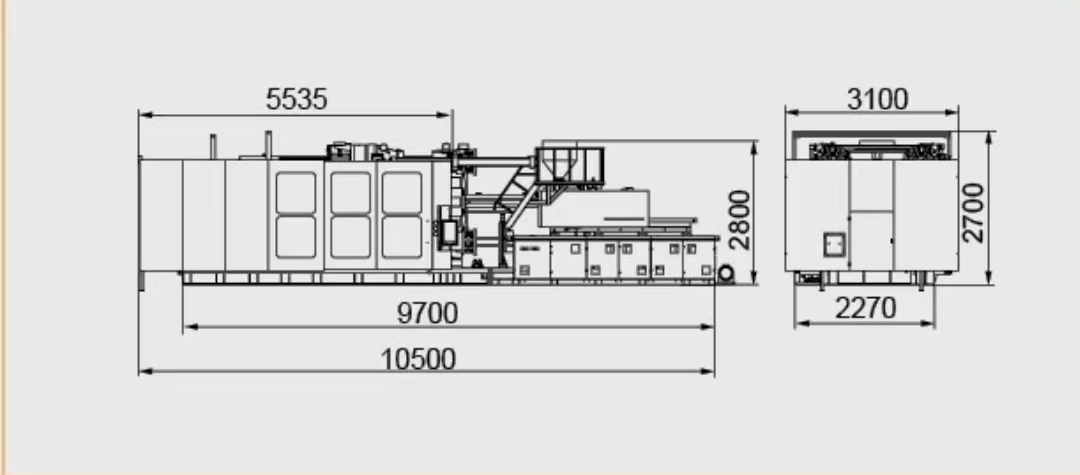

| External dimensions: m | 7.5*2.3*2.3 | 8*2.5*2.5 | 9*2.8*2.7 | 9.8*3*2.8 | 10.5*3.1*2.8 | ||||||||||

|

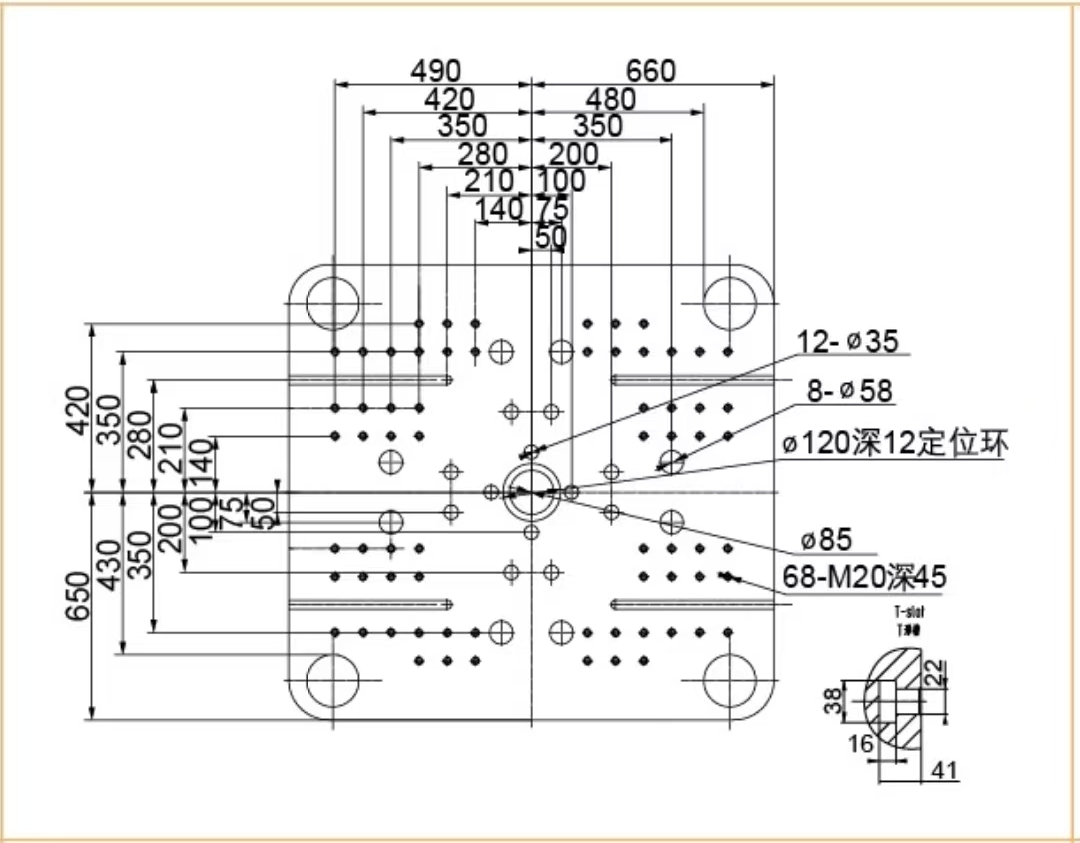

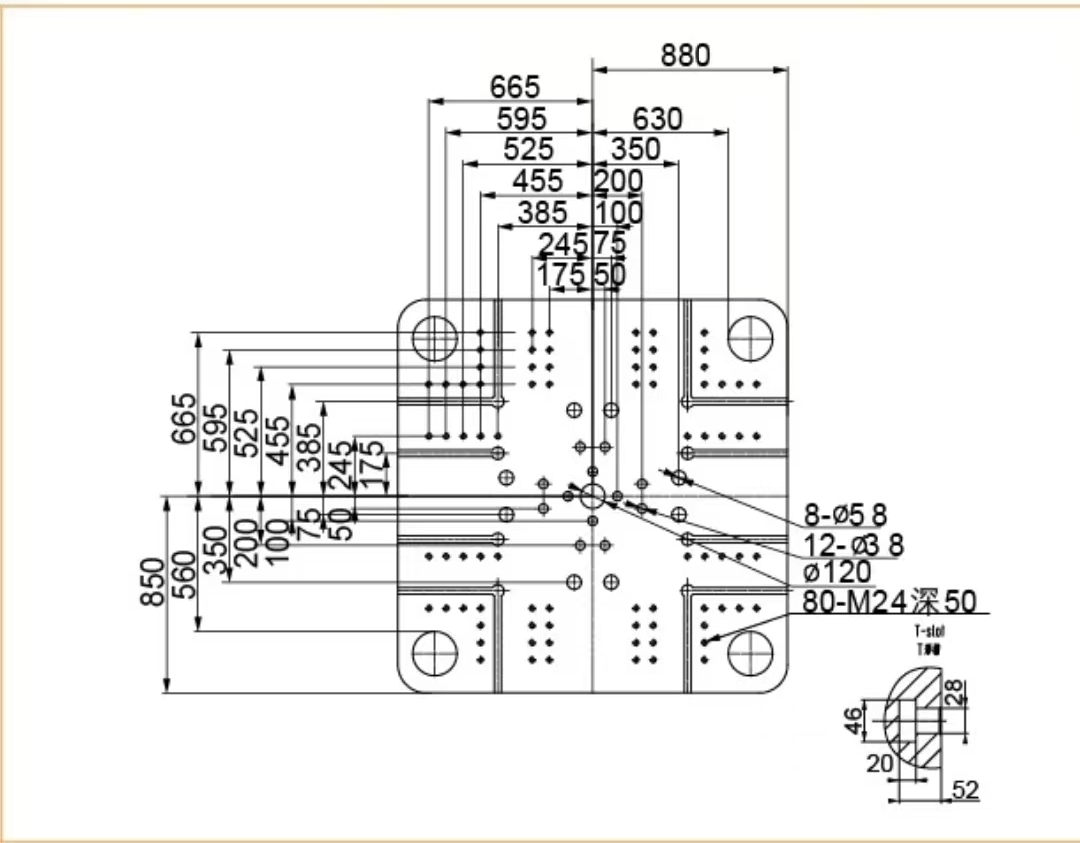

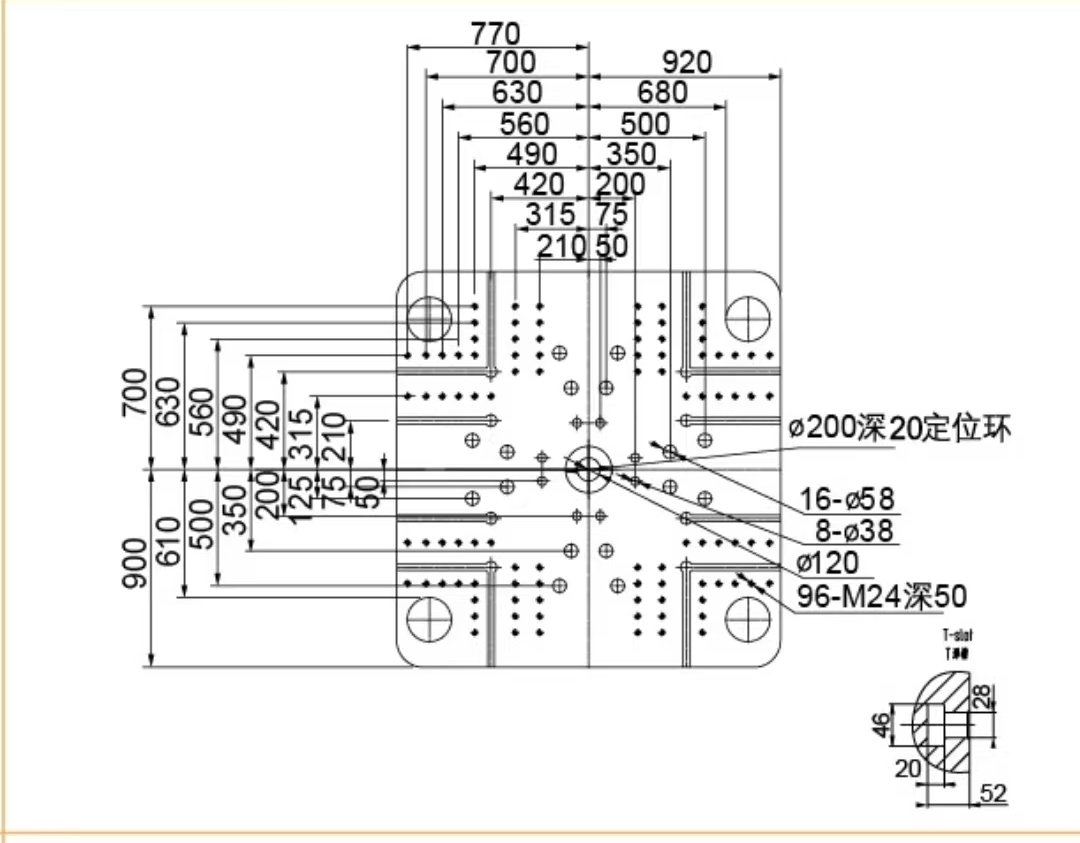

Front dimension of moving template |

|

|

|

|

|

||||||||||

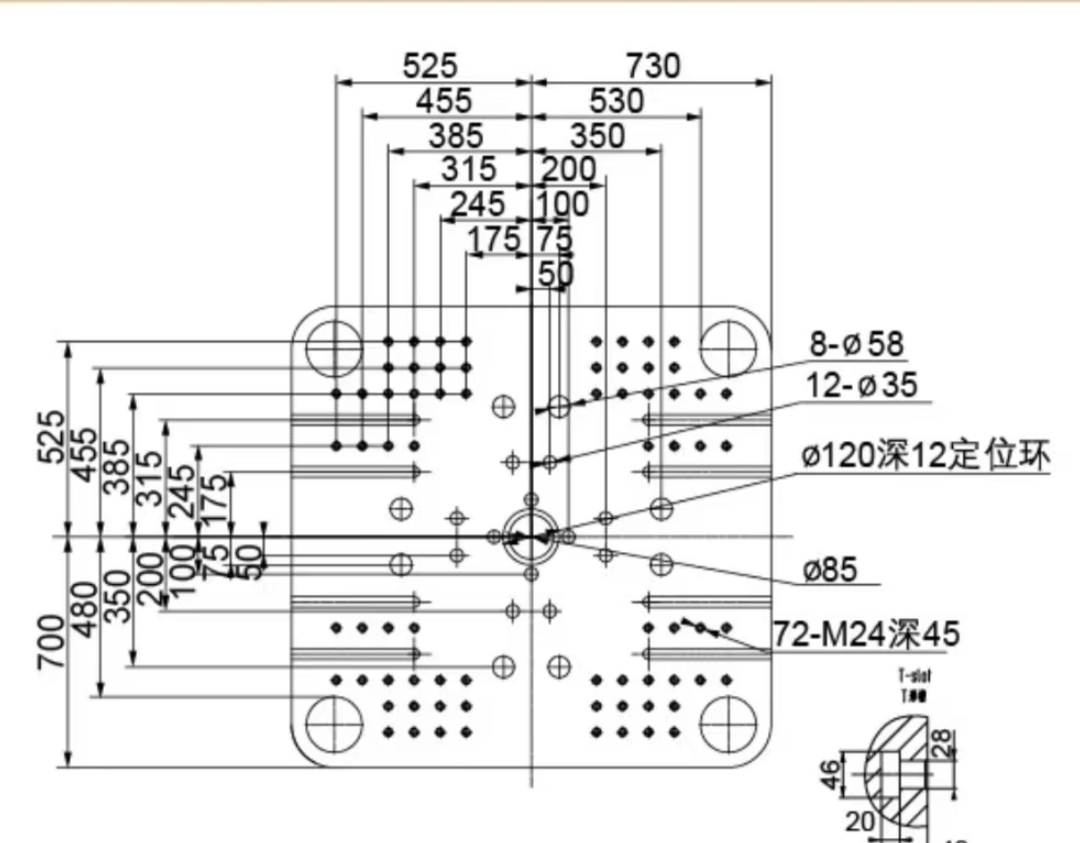

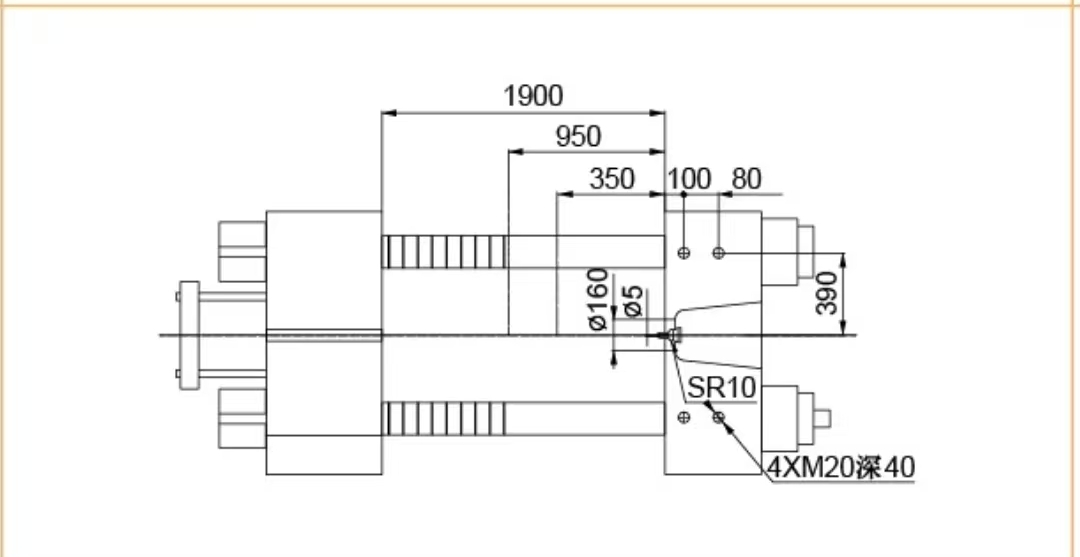

| Template side size |  |

|

|

|

|

||||||||||

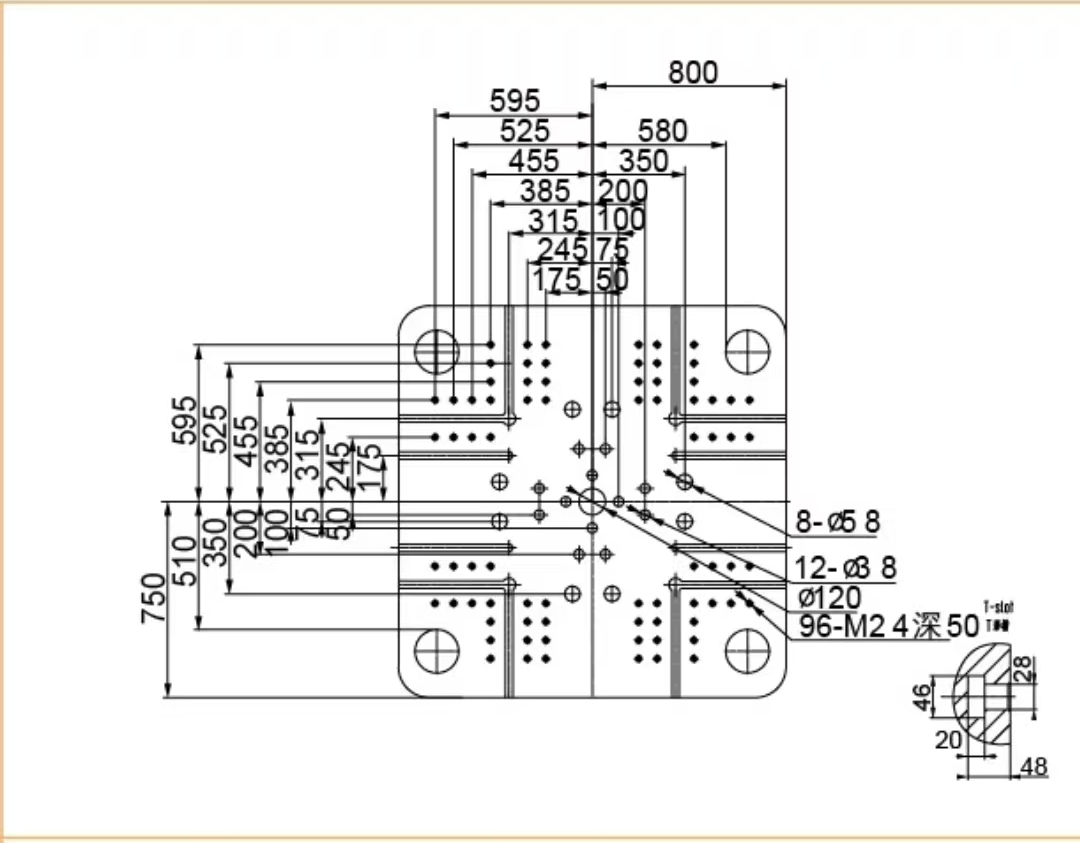

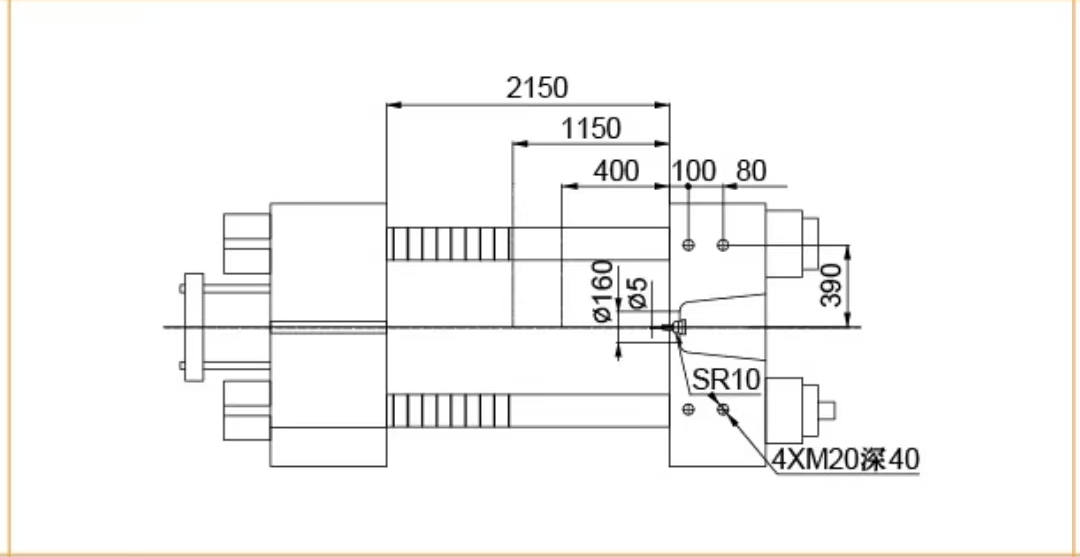

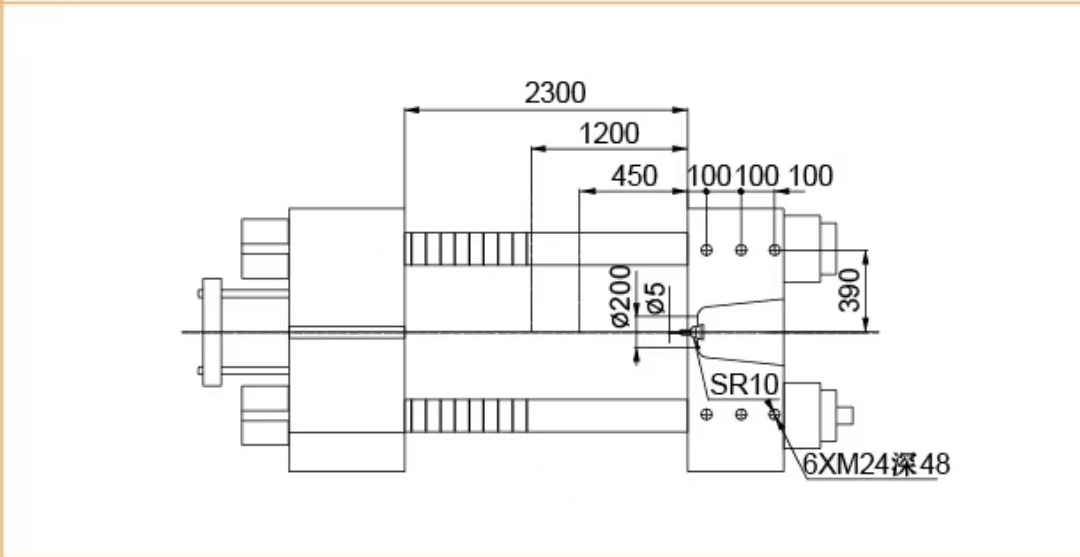

| exterior size |  |

|

|

|

|

||||||||||

The two-platen injection molding machine abandons the middle plate of the traditional three-platen injection molding machine and consists of two templates forming a clamping unit. The overall structure is more compact and concise, and the mechanical rigidity is significantly improved. This allows the template to have minimal deformation when subjected to high clamping force, ensuring the accuracy of mold closing during the injection molding process. It is extremely critical for the production of large-scale, high-precision plastic products, such as auto parts, large home appliance casings, etc., and can effectively Reduce molding defects such as flash.

The two-plate structure reduces the number and stroke of moving parts, making the mold opening and closing movements smoother and more direct, and the mold opening and closing speed is faster. Compared with the three-platen injection molding machine, it can significantly shorten the molding cycle and improve production efficiency. Especially in large-scale and continuous production tasks, every second saved by frequent mold opening and closing can be converted into considerable production capacity improvements over time. .

Template installation convenience

Template installation convenienceThe large two-platen injection molding machine has a larger template size and ample installation space, and can easily adapt to oversized molds. When manufacturing large instrument panels, bumpers and other molds in the automotive industry, there is no need to worry about the mold being unable to be clamped, and the installation process is relatively simple, which reduces mold replacement and debugging time, and enhances the flexibility of the equipment for the production of different large products.

The advanced two-platen injection molding machine is equipped with a high-precision injection system. The screw diameter and stroke design are more suitable for precise metering and stable plasticization of large doses of plastic raw materials. When injection molding large products, a large amount of plastic needs to be injected at one time, the error of each injection amount can still be ensured to be extremely small, so that the product has uniform density, consistent weight, and high quality stability. Large plastic pipes have strict requirements on wall thickness uniformity. Products can also be accurately formed. Energy Saving and Cost Effectiveness

Efficient energy use:

Efficient energy use:Due to the streamlined structure, reduced friction loss of moving parts, and optimized hydraulic or electric drive systems, large two-platen injection molding machines consume significantly less energy during operation. After long-term operation, the power cost can be saved a lot compared with traditional injection molding machines, which reduces the company’s production costs and improves the price competitiveness of the product in the market.

The reduction in the number of parts means fewer failure points, and the workload of daily inspections and maintenance will be reduced. The frequency and cost of repairing and replacing parts will also be reduced. Enterprises do not need to invest too much manpower and material resources in equipment maintenance, and can More resources are invested in production and research and development.

Large two-plate injection molding machines are widely used. In the automotive field, they shape bumper covers and dashboard parts, ensuring precise, large-scale production to meet strict vehicle quality demands. For home appliances, they mold refrigerator shells and washing machine cabinets, providing strong, seamless enclosures. In construction, large plastic pipes and decorative panels for facades rely on them for accurate, high-volume output. Furniture makers use them to produce sturdy plastic table tops and chair seats. Even in the toy and sports goods sectors, they create big playhouses and kayak hulls, thanks to their large clamping force and injection capacity.

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine