- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

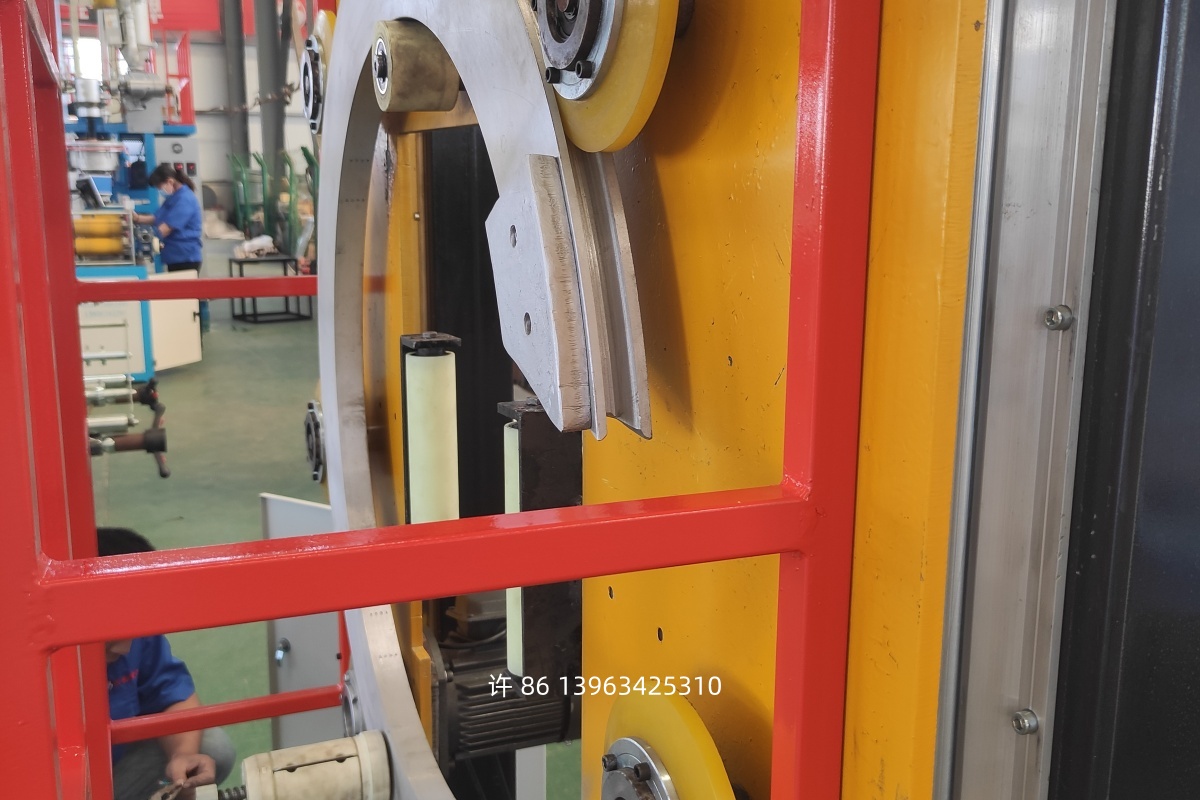

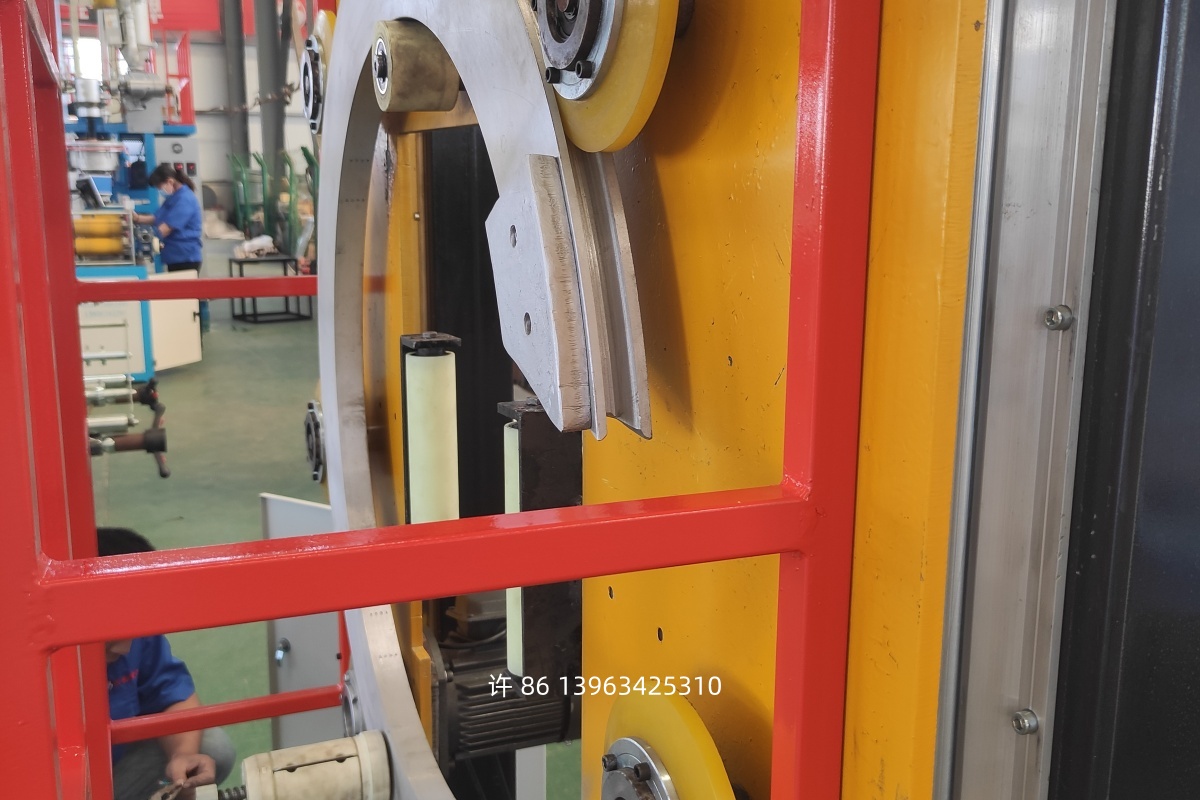

The new double trend air ring is a key component of plastic blown film. It has upper and lower double trends to form three-dimensional air cooling, efficient and uniform cooling, and is also equipped with an independent adjustment device for precise temperature control. Suitable for a variety of plastics, energy saving and compact, it effectively guarantees the fast and high-quality setting of the film, and improves the production efficiency and quality of the blown film.

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

| Category | Details |

|---|---|

| Basic Information | – Product Name: New Double-air Outlet Fan – Brand: Zhengbensource – Place of Origin: Laiwu, Shandong |

| Design Principle | – Air Outlet Structure: It adopts a unique double-air outlet layout. The main air outlet focuses on strong air supply, quickly pushing a large amount of air; the auxiliary air outlet surrounds the main one, helping to fine-tune the air flow direction. The two work together to make the air field more balanced and stable, reducing dead air zones. – Air Duct Design: Based on aerodynamics, the internal air ducts are designed with a smooth streamline shape, which effectively reduces air flow friction, enhances the efficiency of wind energy conversion, and lowers the noise generated during operation. |

| Performance Parameters | – Air Volume Range: The minimum air volume is approximately 15 cubic meters per minute, and the maximum air volume can reach 45 cubic meters per minute, meeting the ventilation needs of daily and some industrial scenarios. – Air Speed Adjustment: There are 3 levels of air speed adjustment, with the air speed ranging from 2 m/s to 5 m/s, which can be flexibly switched as required. – Air Pressure: The average rated air pressure is around 180 Pascals, ensuring the continuity and stability of air flow during long-distance ventilation. |

| Material and Process | – Housing Material: High-quality aluminum alloy is selected. It is lightweight, has high strength, and can withstand a certain degree of impact, corrosion, and high-temperature environments, ensuring long-lasting durability. – Fan Blade Material: Aviation aluminum is used. After high-precision die-casting and fine dynamic balance adjustment, it is lightweight, tough, and can maintain low-noise and stable operation. – Surface Treatment: The housing undergoes anodizing treatment, which improves the aesthetic appearance and endows it with excellent anti-fouling, wear-resistant, and antioxidant properties. |

| Energy Consumption and Energy Saving | – Power: The operating power ranges from 25 watts to 120 watts, with different power consumptions corresponding to different air speed levels. – Energy Saving Feature: Incorporating energy-saving motor technology, it can achieve an energy-saving rate of about 18% compared to traditional single-air outlet devices of the same type. |

| Control and Operation | – Control Method: It is equipped with both mechanical knobs and electronic buttons for simple and intuitive operation; some smart models support remote control via mobile apps, allowing real-time monitoring of the device’s operating status and precise adjustment of air volume and speed. – Timer Function: It comes with a built-in timer setting, with a duration range from 20 minutes to 6 hours, making it convenient to plan the ventilation time in advance. |

| Installation and Maintenance | – Installation Method: It supports wall-mounted, ceiling-mounted, and floor-standing installations. A complete set of suitable installation accessories is included, along with detailed graphic installation guides. – Cleaning and Maintenance: It has a detachable front grille for easy regular cleaning of the dust on the fan blades. The key internal components are sealed for protection, reducing the difficulty and frequency of maintenance. |

| Application Scenarios | – Industrial Scenarios: Ventilation and air exchange in small factory workshops and simple warehouses, helping to dispel dust and hot air. – Commercial Scenarios: Adjusting indoor air circulation in convenience stores and small restaurants to improve environmental comfort. – Home Scenarios: Daily ventilation in living rooms and bedrooms, cooperating with air purification equipment to optimize the home air quality. |

| After-sales Support | – Warranty Period: A 12-month warranty service is provided from the date of purchase. During the warranty period, free repair and replacement of parts will be carried out for non-human-induced damages. – After-sales Team: A professional after-sales customer service team is available to respond to inquiries at any time, and technicians will be dispatched for on-site service when necessary. |

With two trends, forming a three-dimensional air cooling pattern, compared with the traditional single trend, it can take away the heat of plastic film bubbles from more dimensions, accelerate cooling and setting, and significantly improve production efficiency, especially suitable for high-speed blown film production lines.

Unique air duct design and trend layout, after fine adjustment, can output a stable, uniform air flow, to ensure that all parts of the film bubble cooling degree consistent, effectively avoid the film wrinkles caused by uneven cooling, thickness deviation and other defects.

Each trend is equipped with an independent air volume and wind speed adjustment device, allowing the operator to flexibly adjust the cooling temperature and stabilize the film quality according to different plastic materials and film thickness requirements.

Thanks to the optimized wind path and the combination of high-efficiency fans, while achieving the ideal cooling effect, the fan energy consumption is reduced, and long-term operation can reduce a lot of power expenses for enterprises.

It can be adapted to a variety of plastic raw materials, whether it is commonly used polyethylene, polypropylene, or functional plastics, and can be smoothly cooled under its blowing to meet diverse film production requirements.

The overall structure design is scientific and reasonable, compact and does not take up too much space, and adopts high-strength alloy material, which can withstand the vibration and high temperature of the production environment, is stable and durable, and reduces the frequency of maintenance.

The new double trend air ring is widely used in the field of plastic film production. In the manufacture of agricultural film, whether it is an ordinary plastic film made of polyethylene or a special agricultural film with anti-aging, weeding and other functional additives, the double trend air ring can quickly cool the film bubble, making the film thickness uniform, flat and smooth, and ensuring stable light transmission and thermal insulation performance after the agricultural film is laid. In the production of packaging film, for the high-transparency and high-toughness polypropylene film required for food packaging, it uses precise double trend cooling to help the film form with higher accuracy, avoid the problem of crystal point and uneven fog, and meet strict packaging hygiene and appearance standards. At the same time, in the blow molding of industrial moisture-proof and dust-proof plastic films, the double trend wind ring also relies on efficient cooling and uniform wind field to improve film quality, help stabilize production, and adapt to the rhythm of high-speed production lines.

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine