- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

The oil-electric hybrid injection molding machine combines the advantages of oil and electricity. It saves significant energy, saves 30% -60% electricity than pure hydraulic presses, and forms faster. With both the high precision of motors and the strong power of hydraulics, it can flexibly adapt to multiple processes, stable operation and reduce failures. Although the purchase price is slightly higher, long-term use can reduce costs and help injection molding production improve quality and efficiency.

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

| model number | IU200 | IU400 | ||||

|---|---|---|---|---|---|---|

| injection part | A | B | C | A | B | C |

| Injection volume cm ^ 3 | 333 | 416 | 530 | 552 | 688 | 863 |

| Injection volume (PS) g | 303 | 380 | 482 | 502 | 625 | 785 |

| Screw diameter mm | 42 | 47 | 53 | 52 | 58 | 65 |

| Screw length-diameter ratio Sc | 27:1 | 24:1 | 22:1 | 27:1 | 24:1 | 22:1 |

| Air injection rate cn ^ 3/s | 485 | 607 | 773 | 425 | 530 | 664 |

| Maximum injection pressure Mpa | 230 | 183 | 144 | 225 | 180 | 144 |

| Maximum holding pressure Mpa | 185 | 146 | 115 | 180 | 143 | 115 |

| Maximum plasticizing capacity (PS) g/s | 35 | 48 | 66 | 60 | 90 | 115 |

| Injection stroke mm | 240 | 260 | ||||

| Maximum screw speed rpm | 400 | 400 | ||||

| Maximum injection speed mm/s | 350 | 200 | ||||

| Injection + storage motor power Kw | 47+26 | 58+37 | ||||

| Electric heating power Kw | 22 | 26 | ||||

| Temperature control zone | 5 | 5 | ||||

| clamping part | HS260 | HS330 | HS400 | |||

| Junction force Kn | 2800 | 3300 | 4000 | |||

| Maximum die transfer stroke mm | 550 | 620 | 730 | |||

| Tie rod inner spacing (WxH) mm | 610*570 | 680*660 | 730*730 | |||

| Maximum template distance mm | 1180 | 1300 | 1530 | |||

| Die thickness mm | 180-630 | 220-680 | 280-800 | |||

| Ejection stroke mm | 160 | 180 | 200 | |||

| Maximum ejection thrust Kn | 99 | 125 | 152 | |||

| System pressure Mpa | 17.5 | 17.5 | 17.5 | |||

| Oil pump motor power Kw | 35 | 43 | 55 | |||

| 其它 | ||||||

| Fuel tank capacity L | 350 | 400 | 600 | |||

| Total weight: t. | 9 | 12 | 15 | |||

| Dimensions (LxWxH) m | 6.3*1.56*2.2 | 6.6*1.63*2.2 | 7.2*1.75*2.2 | |||

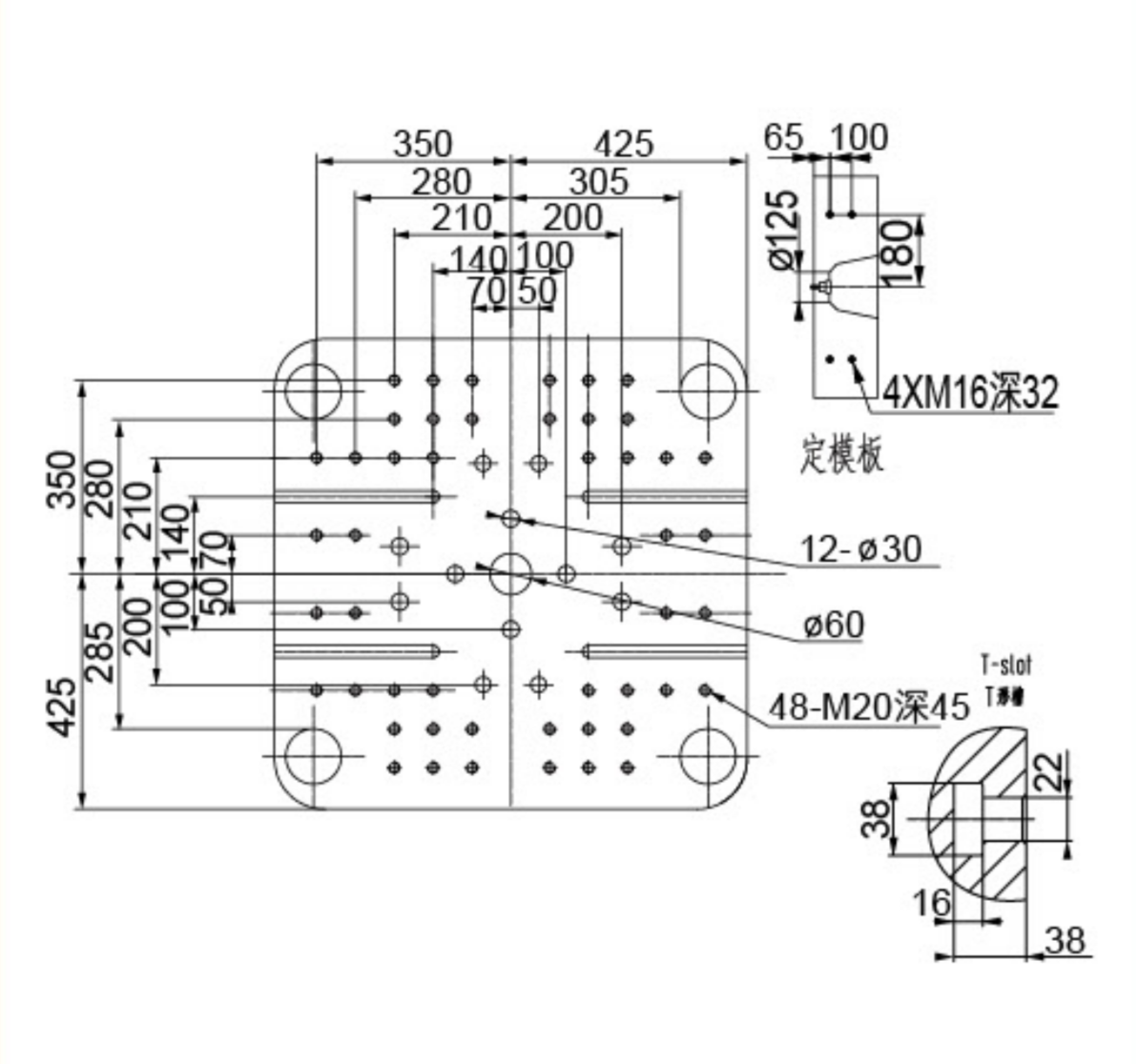

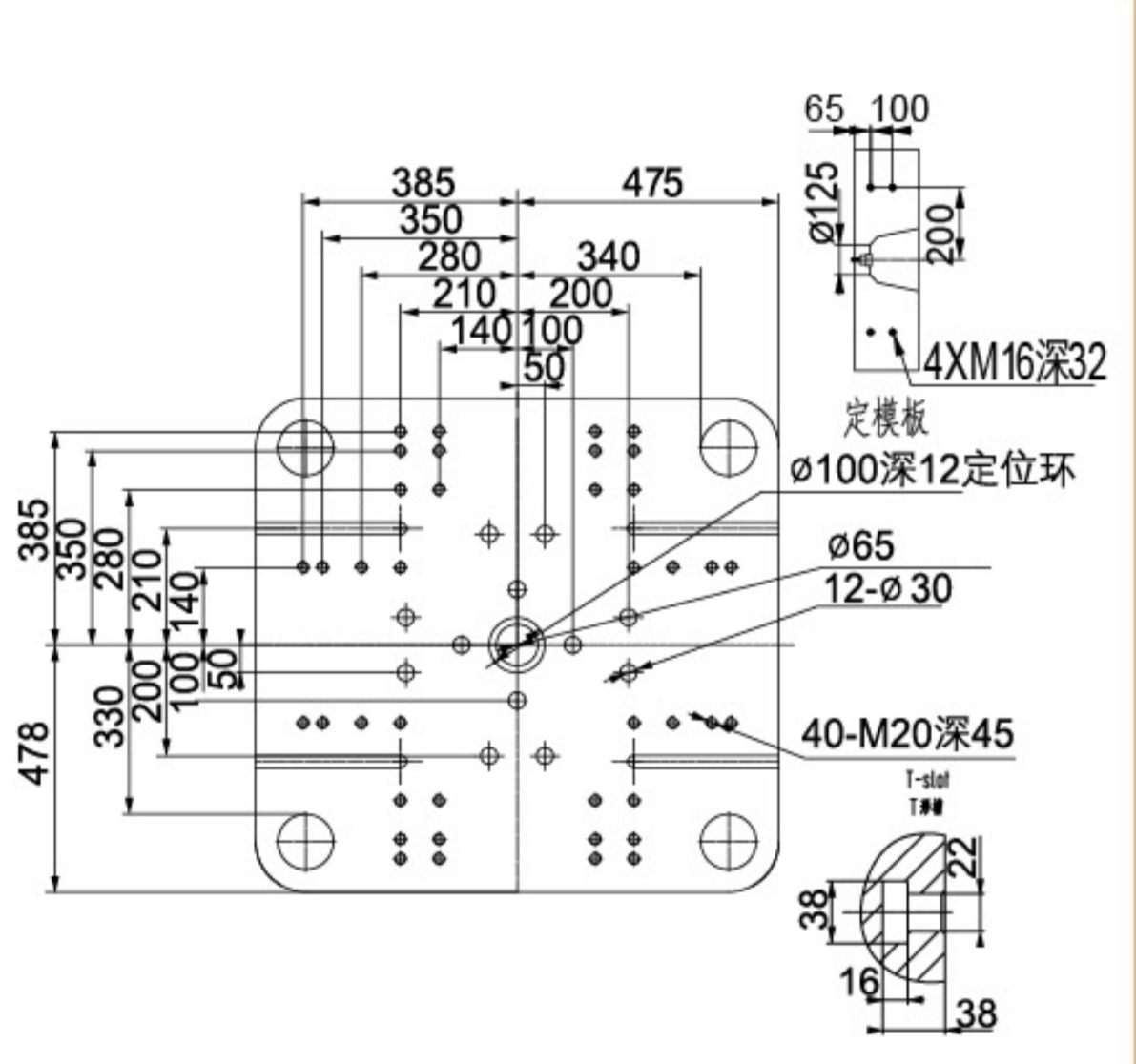

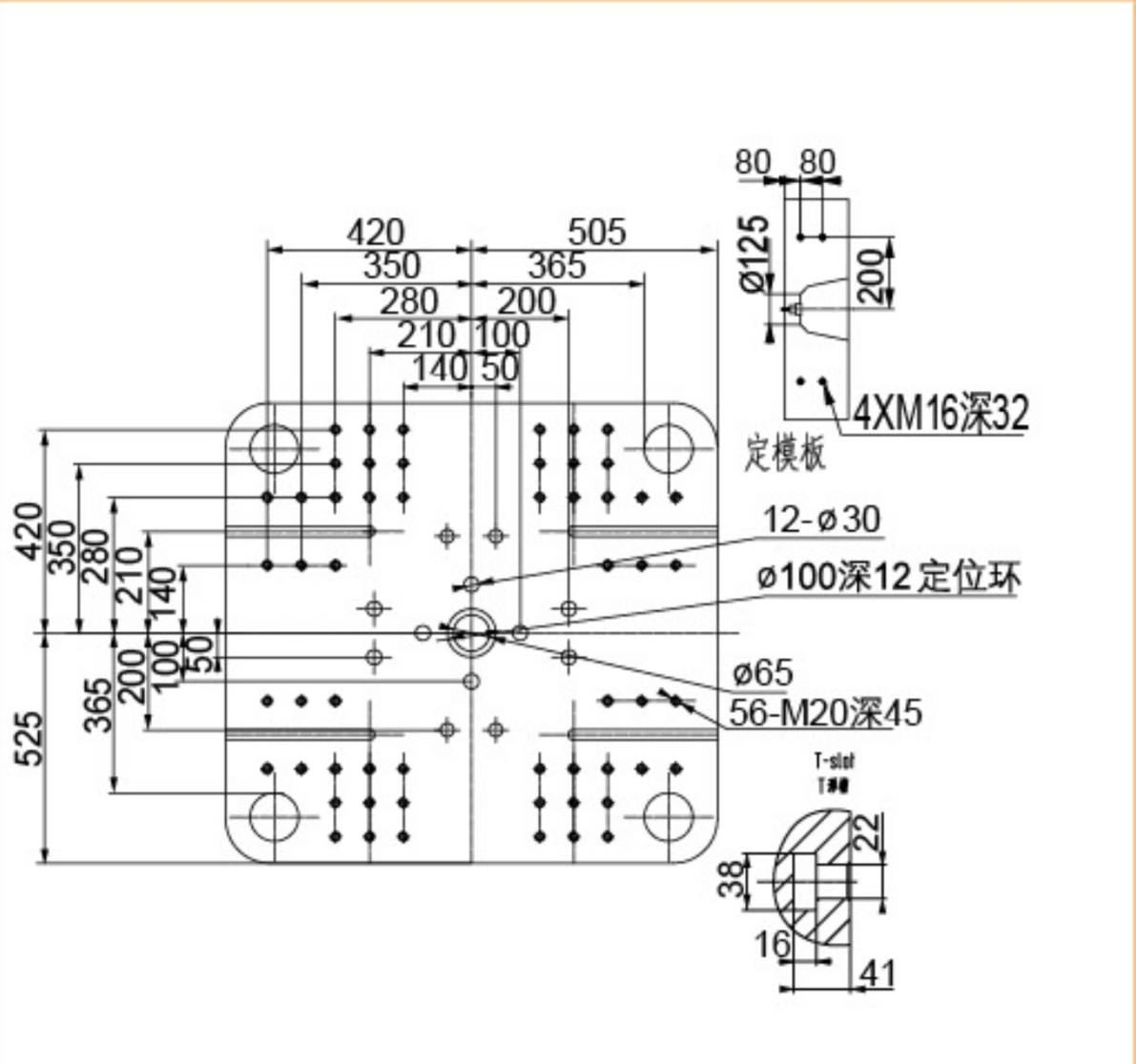

| Front dimension of moving template |  |

|

|

|||

in the opening and closing of molds, ejecting and other actions, the motor is used for precise drive, low energy consumption; injection, plasticization and other high-load links use hydraulic systems, which not only ensure strong power, but also save 30% to 60% energy compared with pure hydraulic injection molding machines, shorten the molding cycle, and increase the output per unit time.

The motor is responsible for movements such as opening and closing molds, with an accuracy of up to millimeters. With an advanced control system, the injection pressure and speed are carefully regulated, and the dimensional accuracy deviation of the product can be controlled within a very small range to ensure high-quality molding results.

Inheriting the advantages of the hydraulic system, when facing large, complex molds and high-viscosity plastics, the hydraulically driven injection unit can provide continuous and strong injection force, ensuring that the plastic melt fully fills the mold cavity, so that thick-walled or complex plastic products can also be perfectly formed.

Combining the advantages of oil and electric drive modes, it can flexibly switch drive modes and parameters according to different plastic characteristics and product structures, easily responding to the diverse production needs from thin-walled packaging to heavy industrial parts, and adapting to various injection molding processes.

Reduce the performance fluctuation caused by the change of oil temperature in the pure hydraulic system, and also avoid the risk of power failure that may occur in the all-electric system. The oil and electricity work together to keep the equipment in a stable state for a long time, reduce the failure rate, and extend the service life of the equipment.

Although the procurement cost is slightly higher than that of traditional hydraulic injection molding machines, the energy saving effect is significant, and the electricity cost is greatly reduced after long-term operation. During maintenance, the cost of manpower and accessories is also reduced due to the long service life and few failures of components.

The oil-electric hybrid injection molding machine has a wide array of applications. In the automotive industry, it’s used to produce high-precision parts like dashboard panels and interior trim pieces. These components need excellent surface quality and dimensional accuracy, which the hybrid machine can deliver while saving energy. For home appliances, it manufactures parts for refrigerators, washing machines, and air conditioners, ensuring seamless, robust casings. In the electronics sector, it molds precise plastic enclosures for smartphones, tablets, and chargers. Additionally, in the toy-making field, it creates detailed and durable plastic toys, combining power and precision to meet diverse production demands.

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine