- +86 139 6342 5310

- [email protected]

- 140 Wenhua South Road, Laiwu District, Jinan City, Shandong Province

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

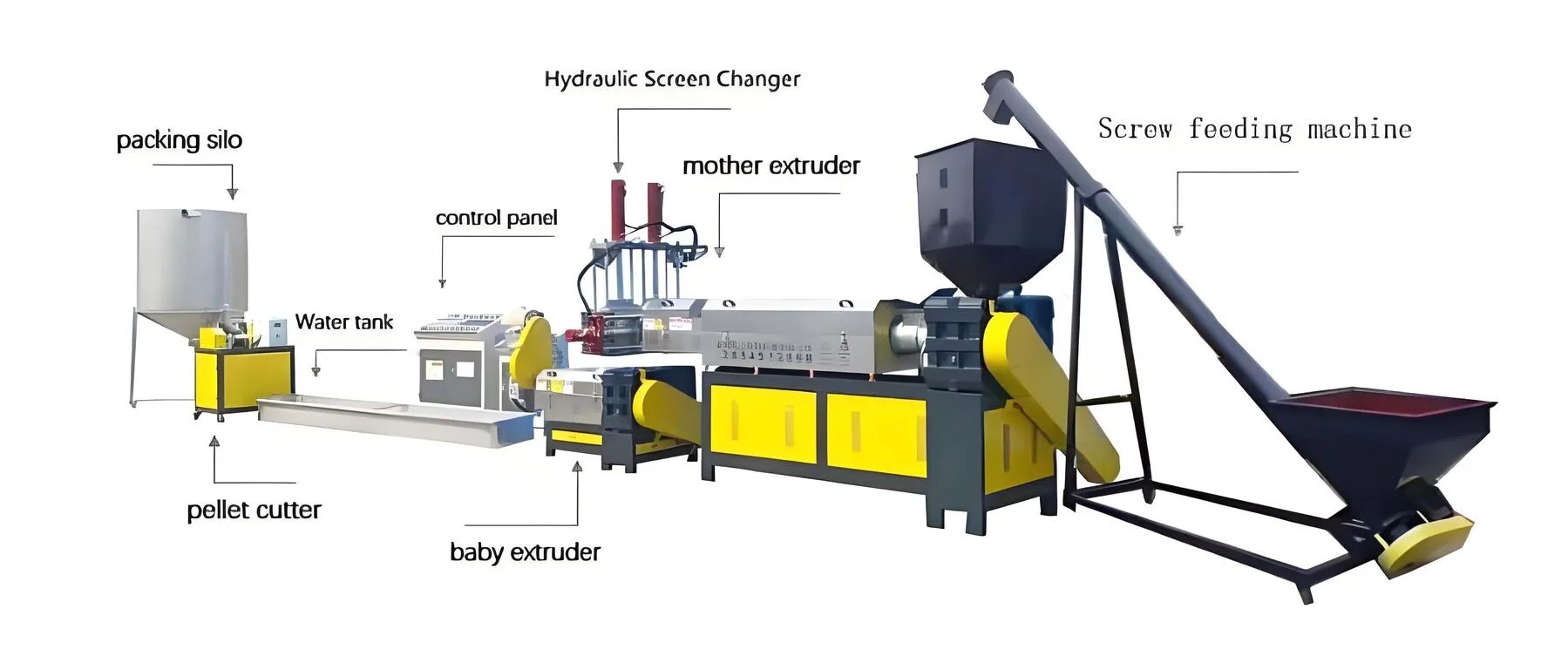

The PP PE hard material granulator is composed of the main machine and the auxiliary machine. It adopts a double-stage design, first strongly plasticizes PP, PE and other hard materials, and works together with the mother and child screws to efficiently mix, exhaust, and filter impurities. It has a high degree of automation and low energy consumption. It can stably produce high-quality and uniform plastic particles, which are suitable for diverse production needs.

![]() Whatsapp : +8613963425310

Whatsapp : +8613963425310

![]() Email : [email protected]

Email : [email protected]

Product details:

Product details:| serial number | name | configuration | picture | power | power |

|---|---|---|---|---|---|

| 1 | Feeder (strong magnetic type) | Working width: 400mm Working length: 4000mm Feeding method: circular track The roller is equipped with strong magnetic adsorption |

|

1.5kw | 1 |

| 2 | 150 host | Screw length: 2600mm Screw material: 38CrMoAL Screw diameter: 150mm Screw length: 2500mm Screw material: 38CrMoAL Rack: 14 #channel steel integral welded frame Gear reducer: 315 national standard hard tooth surface Heating: Electromagnetic heating 40kw two groups Die head: 300 double station double screen plate hydraulic Stainless steel feed hopper is installed at the feed port of the main engine Hopper size: 800x800x1000mm |

|

75Kw (with inverter) | 1 |

| 3 | 140 auxiliary machine | Screw length: 1400mm Screw material: 38CrMoAL Screw diameter: 1140mm Screw length: 1300mm Screw material: 38CrMoAL Rack: 10 #channel steel integral welded frame Gear reducer: 280 national standard hard tooth surface Heating: stainless steel thermal insulation heating ring Die head form: 300 double station double screen board (with strip ejector installed) |

|

30kW (with inverter installed) | 1 |

| 4 | 200 granulator | Blade form: hob Blade length: 250mm Blade material: alloy Number of blades: 22 teeth Tool holder form: gantry |

|

3-6kw (equipped with frequency converter) | 1 |

| 5 | Cooling tank | Size: 300 * 450 * 5000mm Material: 201 stainless steel Install an independent slitting rack |

|

1 | |

| 6 | storage bin / silo | Material: 201 stainless steel Reserves: 2T |

|

2.2kw | 1 |

| 7 | control cabinet | Seven-zone constant temperature digital control Current and voltage display Host, auxiliary machine start and shut down Host, auxiliary fuselage partition section heating control One key control of main power supply Chint components |

|

1 | |

| 8 | Blowing and cutting strip integrated machine | Working width: 400mm Working length: 2400mm Overall material: stainless steel |

|

Blowing bar power: 240w Stripping power: 0.75kw |

1 |

| 9 | vibrating screen | Screen length: 1500mm Number of screens: 2 Screen material: stainless steel Screen aperture: 8mm |

|

1 |

The special screw design and heating and cooling system can make full use of high-pressure friction to continuously heat up, saving electricity and energy compared to traditional granulators. At the same time, the dual-stage design of the sub-machine allows materials to be processed more fully at different stages, improving production efficiency and reducing energy consumption.

With good material handling and plasticizing capabilities, it can achieve continuous and uninterrupted production, reduce downtime and production cycles, and improve equipment utilization and productivity.

The entire process from raw material crushing, cleaning, feeding to granulation can be automated, reducing manual intervention, reducing labor intensity and labor costs, and also improving production stability and product quality consistency.

The screw and cylinder are designed on the principle of building block, which can be optimized according to the characteristics and process requirements of PP and PE materials, so that the materials can be fully plasticized and mixed in the machine, and the particles produced are uniform and dense in texture, bright in color and good in plasticizing effect.

The secondary filtration and exhaust effect of the mother machine is good, which can effectively remove impurities and bubbles in the material, making the produced particles more pure and free of pores, thus improving the quality and performance of the product.

The overall structure design is reasonable, the footprint is small, and the production space is saved. At the same time, the connection between the components is tight, the operation is smooth, and the vibration and noise of the equipment are reduced.

The screw barrel is usually made of imported high-strength high-quality carbon structural steel, which has good wear resistance and corrosion resistance and is durable, reducing the maintenance and replacement costs of the equipment.

The key components of the equipment are easy to disassemble and replace, and opening the axial splitting barrel ensures easy cleaning and quick maintenance, reducing the difficulty and maintenance time of the equipment and improving the operating efficiency of the equipment.

It is suitable for a variety of plastic raw materials such as PP and PE, including new materials, recycled materials, and mixtures with various fillers and additives, to meet the production needs of different users.

Multi-functional production can be achieved: by replacing different molds and adjusting process parameters, granular products of different specifications and uses can be produced, such as plastic granules used in injection molding, extrusion, blow molding, and other processing processes, achieving multi-purpose in one machine, improving the economy and practicality of the equipment.

Plastic product processing: provides raw materials for injection molding plants to produce various types of plastic toys, stationery, household goods, etc.; during extrusion molding, it is used to manufacture pipes and profiles, such as PPR water pipes, PE plastic steel door and window profiles, to ensure product quality and performance stability.

Packaging industry: The particles produced are used in the blow molding process to produce plastic films and bottles, which are commonly used in food and daily chemical product packaging and have good barrier properties and toughness.

Agricultural field: The PP and PE particles produced can be processed into agricultural water pipes and agricultural films, which can help irrigation and crop insulation and moisturization. They have good weather resistance and can be used outdoors for a long time.

Building materials decoration: Made of plastic particles for the production of plastic flooring, gusset, cost control and easy installation, beautiful and durable, providing a wealth of material options for home improvement and tooling projects.

Recycled plastics recycling: Dispose of waste PP and PE plastics, so that waste resources can be regenerated and converted into usable particles, which not only reduces costs but also promotes the circular development of the plastics industry.

Our PVC pipe production line can adapt to a wide range of environmental conditions. The recommended working temperature is 0 – 40°C, and it can operate normally with a relative humidity not exceeding 85%. If your factory has special environmental conditions, we can provide targeted protection solutions, such as installing temperature control equipment and moisture-proof treatment, to ensure the stable operation of the equipment.

The core components of our equipment are designed in a standardized manner, and common accessories are well-stocked. For domestic customers, the goods can be delivered within 3 – 5 working days after the order is placed. For specially customized components, we will closely cooperate with suppliers to ensure delivery within 15 – 20 working days, minimizing the impact on your production.

Certainly! We not only provide equipment but also share our accumulated production process experience according to your product requirements. Our technical experts will formulate detailed production process plans combined with the characteristics of the equipment and provide on-site guidance and optimization during the equipment debugging stage to help you produce high-quality products.

Our drip irrigation pipe production line is equipped with a fully automatic control system, enabling a full – process automation from raw material feeding to finished product winding. Compared with traditional production lines, it can reduce labor input by 60%. For example, a production line with a daily output of 2 tons only requires 2 – 3 operators to complete the production, significantly reducing labor costs.

Of course! For customers who make bulk purchases or purchase multiple product categories, we will provide tiered discount offers based on the specific purchase amount and equipment type. At the same time, we will also give away a certain number of vulnerable parts and extend the equipment warranty period, making your purchase more cost-effective.

We have fully considered noise control in the equipment design. Through optimizing the mechanical structure and installing sound insulation devices, the running noise is lower than the national industrial noise standard (≤85 decibels during the day and ≤75 decibels at night). The equipment’s energy consumption, exhaust emissions, and other indicators meet environmental protection requirements and have passed relevant inspection and certification, so you can use it with confidence.

The overall warranty period for our plastic machinery is 1 year, and the warranty period for core components is 2 years. During the warranty period, all costs for repairs and component replacements due to equipment quality problems will be borne by us, and you do not need to pay any additional fees. After the warranty period expires, we will still provide preferential maintenance services and component prices.

We cooperate with multiple financial institutions and can provide flexible financing plans for customers, such as installment payments and equipment leasing. You can choose the down payment ratio and repayment period according to your own financial situation to ease financial pressure and smoothly introduce the equipment for production.

Customized plastic machinery experts help customers seize market opportunities with technological breakthroughs

Welcome to Z.B.Q.Y. Plastic Machine